Ultra Fine Pulverizer Trial Run Result

Installation Information: September 2023 in Thailand. Official trial runs in October.

Machine model: SCW30

The main grinding motor power: 30 kW

The grading motor power: 3 kW, frequency conversion

Centrifugal fan motor power: 11 kW

Auger screw motor power: 0.55 kW, frequency conversion

Airlocks x2 motor power: 0.75 kW

Machine lubrication uses Lithium-based # 2 grease.

SCW30 Ultra Fine Pulverizer Installed in Thailand

The ultra fine pulverizing machine ran well during commissioning trials. About 80 degrees centigrade for the classifier chamber surface, without using the water cooling function.

Report date: 30th October, 2023

SCW30 Ultra Fine Pulverizer Installed in Thailand

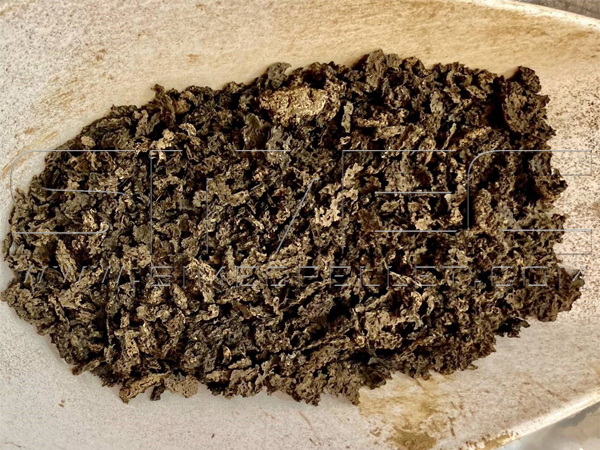

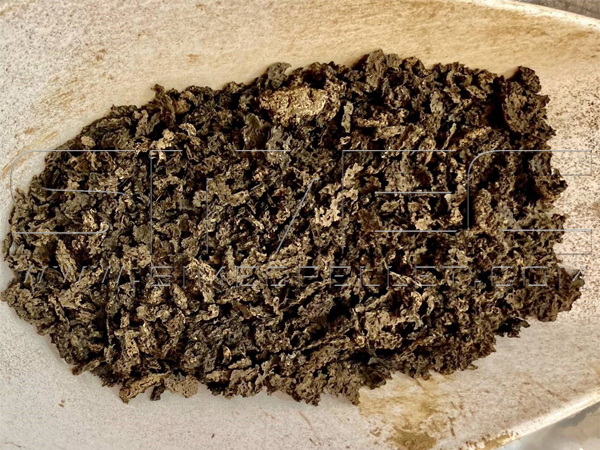

Raw Material:

Dry microbial biomass as a feed supplement in the form of powder/granules, be made from non-viable microbial cell wall fractions derived from a pond-cultured microbial biomass. It contains no viable bacterial or algal cells/spores.

Physical Properties: It is a free flowing, smooth, dry granular powder of 1-5mm particle size. Colour varies (as it is a natural product) from light brown to dark greenish brown in colour. Pleasant earthy, algae-like odour. Density varies from 350-500 g/cm3.

Pulverizing Requirement: be pulverized to 25 micron, about 500-600 mesh.

Pulverizer Operation Settings: auger screw frequency 25 Hz, classifier frequency between 25 Hz and 40 Hz, air damper mid setting.

The ultra fine pulverizing machine ran well during commissioning trials. About 80 degrees centigrade for the classifier chamber surface, without using the water cooling function.

The client should be starting a 4 tonne run the week after the trial stage.

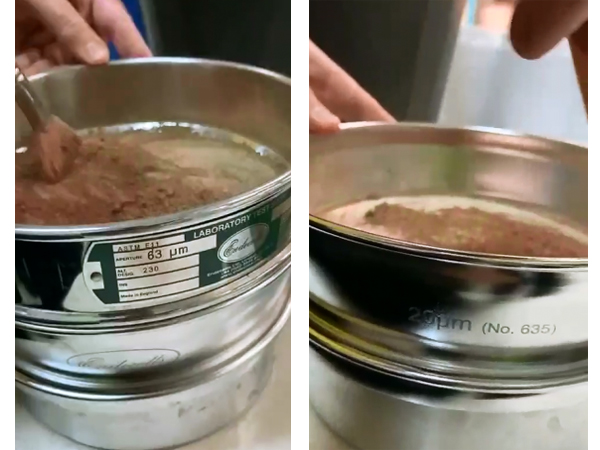

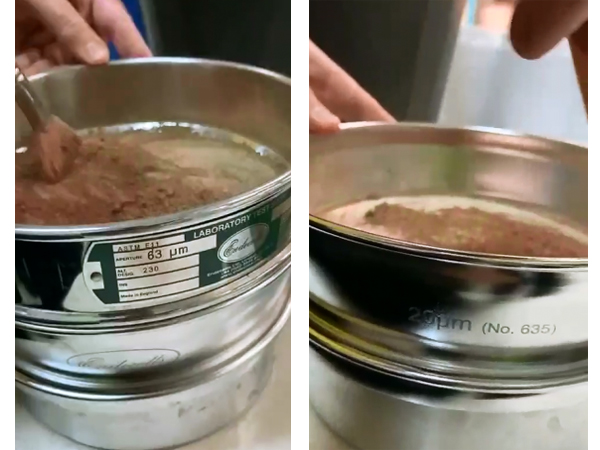

63 micron and 20 micron sieves for first product off machine (air damper mid setting and both frequencies at 25 Hz). The bag filter dust 10 micron.

The dark color powder is from the cyclone and the light from bag filter. Volume ratio 4:1 approx.

The original raw material is dark. This means no color change after pulverizing process.

The product grind size was analysed at a University lab and it was very good (approx 25 micron average for the post cyclone and approx 10 micron for the bag house dust).

There’s a high % of the 10 micron dust, but we can reduce this % by restricting the airflow a bit.

The only adjustments we made during commissioning runs was to the classifier frequency.

The only adjustments we made during commissioning runs was to the classifier frequency.

For more information, please contact SIMEC. Email: info@simecpellet.com Tel: +86 372 5375806