SPM800 RDF Pellet Mill

Refuse Derived Fuel is called RDF for short. RDF is selected from MSW which is short for Municipal Solid Waste.

Pelletization is the value added process to Utilize the Refuse.

SPM800 RDF Pellet Mill is suitable to make RDF pellets with the diameters of 22mm, 24mm and 28mm, customers can use different diameters ring die to produce suitable pellets according to the actual requirements. The requirements will be based on the general analysis of RDF material contents, combustion furnace, transportation and storage, etc. Qualified RDF Pellets will improve the efficiency of fuel handling system, and improve the heat for power generation.

SPM800 RDF Pellet Mill is equipped with high quality die and rollers. It is developed with reliable technology to process RDF into solid pellets.

RDF Pellets

RDF Pellets

The raw material RDF ( Refuse Derived Fuel) with moisture content 18%-23% flows into feeder from hopper and proper flow rate is obtained by adjusting the rotational speed of feeder shaft. Then the material passes the safety magnet for removing the metal impurities, then it passes the feed chute and finally enters the pellet chamber for pelleting. According to our experiences on RDF Pellet Projects, it is recommended to make Diameter 28MM Pellets.

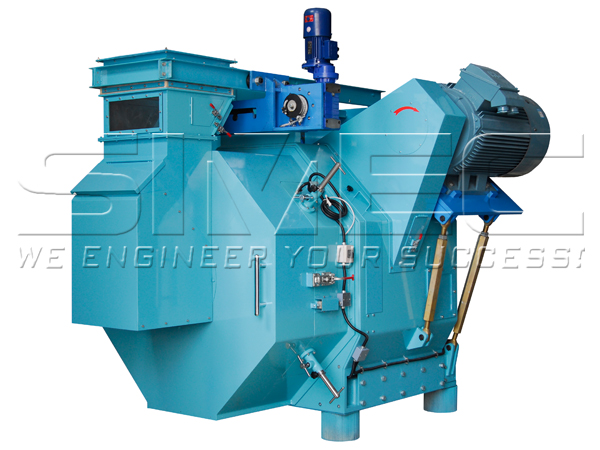

RDF Pellet Mill SPM800

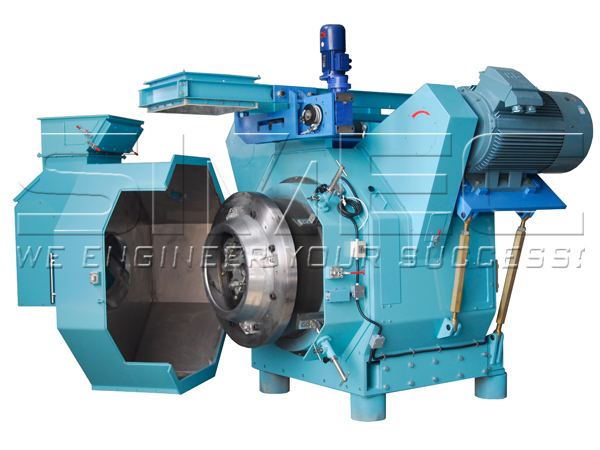

RDF Pellet Mill SPM800 Inside View

| Pellet mill type | SPM800 | |

| Ring die | Inside diameter mm | 800 |

| Capacity T/H | 2~2.5 | |

| Roller | Quantity | 2 |

| Diameter mm | 380 | |

| Main motor | Power Kw | 110Kw*2 |

| Screw feeder |

Motor power Kw Frequency Conversion |

5.5 |

RDF Pellet Mill SPM800

SPM800 RDF Pellet Mill

RDF Pellet Mill In South Korea

RDF Pellet Plant