Hammer Crusher

- Professional wood grinding solution

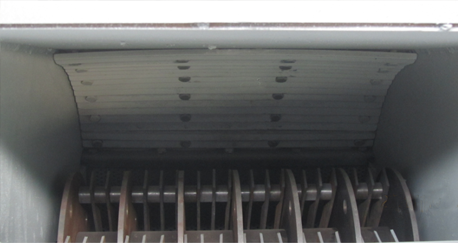

- Special treated hammers and casting chopping block;

- SKF bearings and base for the rotor,reliable quality to guarantee the stable running of rotor;

- Wide crushing room,high efficiency;

- 4.5mm thickness screen to increase the lifespan of spare parts;

- Easy to maintain and replace screen;

- Belt transmission adopts C type belts;

It is professional pulverizer to process wood blocks,chips,etc. The pulverizing room is designed to be wide to crush wood material. Well balanced rotor makes the running very stable.

Magnet detector installed at the inlet

Filter screen installed at the bottom,

chopping block fixed on the main drum.

| Type | Power | Rotor Diameter | Width of crushing chamber | Capacity |

| MFSP63/60 | 37 Kw | 630mm | 600mm | 1~1.5 T/H |

| MFSP80/80 | 55 Kw | 800mm | 800mm | 2~3 T/H |

| MFSP80/100 | 75 Kw | 800mm | 1000mm | 3~4 T/H |

| MFSP80/120 | 90 Kw | 800mm | 1200mm | 4~5 T/H |

While the hammer rotor is working,

the wood will be grinded by the hammers and chopping block.