Drum Chipper

Drum wood chipper (new model) is a kind of special equipment for wood chipping. Widely used in shaving board, chipboard and paper mills and other industrial production.

Feedstock: wood logs,branches,wastes,etc.

Wood chips: size and thickness adjustable

This kind of machine is mainly used to chip wood logs, wood cutting remains (wood branching tree stumps, branches, etc.) and waste material from wood working industry (slab, lath, logs core and waste veneer, etc). Wood chip size is adjustable upon clients’ requirements. It can also cut non-wood materials, like sugar cane, bulrush,gross bamboo and so on.

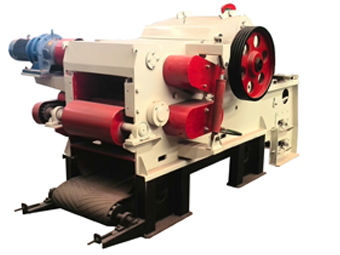

Photos of the drum chippers:

Technical Parameters:

| Type | BX213 | BX215 | BX216 | BX218 | ||

| Knife number | 2 | 2 | 2 | 2 | ||

| Inlet dimension(mm) | 120×300 | 160×400 | 240×540 | 240×680 | ||

|

MAX Diameter of feeded wood(mm) |

90 | 160 | 220 | 240 | ||

| Length of Finished product(mm) | 25 | 30 | 30 | 22 | 30 | 22 |

| capacity(cubic meter/hour) | 3 | 4-5 | 10 | 15-20 | ||

| Main engine(kw) | 30 | 45 | 55 | 110 | ||

SIMEC has more large scale heavy duty wood chippers, which can chip larger wood logs or trunks in diameter above 450 mm till up to 700 mm.

SIMEC drum wood chippers are of advanced structure, high quality material, wide adaptability of raw materials, simple operation and maintenance.

The drum wood chipper can chip various kinds of wood materials into small even sizes of wood chips. Raw material can be wood logs, wood branches, waste wood or artificial boards, and other non-wood panel, etc.

The wood chipper consists of base, knife roller, feeding rollers, belt conveyor and hydraulic system. The main body is welded by the high strengthen steel plate. 2, 3 or 4 pcs of knives would be installed on the knife roller according to the clients’ requirements for the output size of the wood chips. The knives are made of high strengthen alloy steel forge piece. Adopted with the hydraulic system, the feeding of large size raw material is smooth and secure.

With strong and reasonable structure, plus the durable knives, the SIMEC BX drum wood chippers are guaranteed for heavy duty operation.

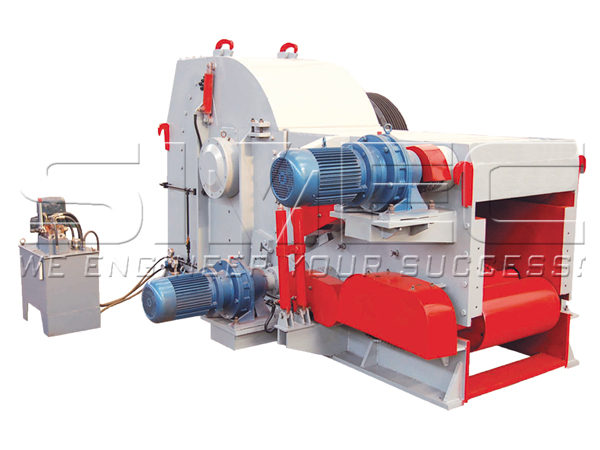

Photos of large scale drum chippers:

SIMEC drum wood chippers are of advanced structure, high quality material, wide adaptability of raw materials, simple operation and maintenance.

The drum wood chipper can chip various kinds of wood materials into small even sizes of wood chips. Raw material can be wood logs, wood branches, waste wood or artificial boards, and other non-wood panel, etc.

The wood chipper consists of base, knife roller, feeding rollers, belt conveyor and hydraulic system. The main body is welded by the high strengthen steel plate. 2, 3 or 4 pcs of knives would be installed on the knife roller according to the clients’ requirements for the output size of the wood chips. The knives are made of high strengthen alloy steel forge piece. Adopted with the hydraulic system, the feeding of large size raw material is smooth and secure.

With strong and reasonable structure, plus the durable knives, the SIMEC BX drum wood chippers are guaranteed for heavy duty operation.

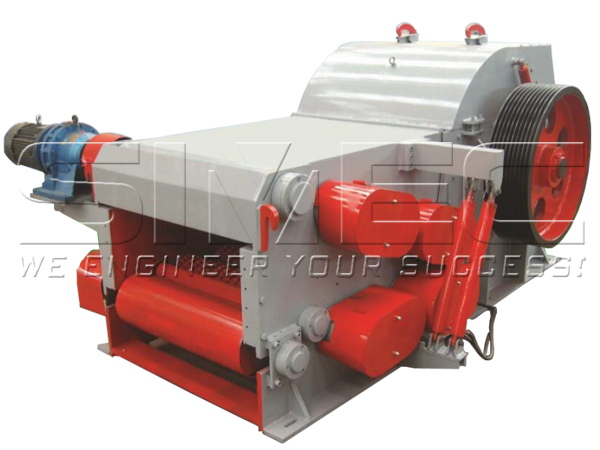

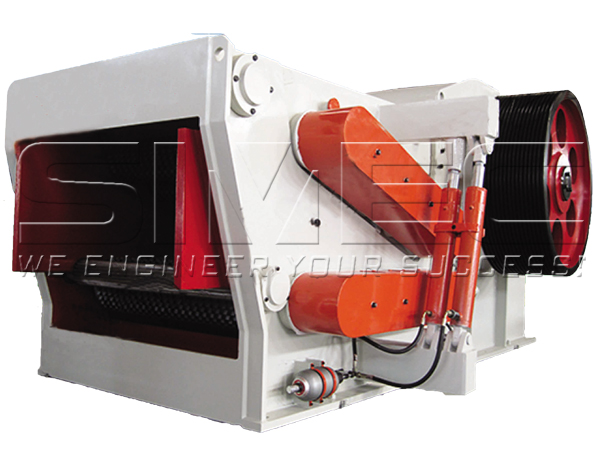

Photos of large scale drum chippers:

BX2113 Drum Chipper

BX2113D Drum Chipper

BX2116 Drum Chipper

| Type | BX2113 | BX2113D | BX2116 | |

| Knife number | 3 | 2*3 | 4*2 | |

| Inlet dimension(mm) | 450*700 | 450*1000 | 600*1250 | |

|

MAX Diameter of feeded wood(mm) |

450 | 450 | 600 | |

| Length of Finished product(mm) | 38 | 38 | 30 | |

| Capacity | 15-30 t/h | 25-40 t/h | 185 M3/h | |

| Main engine(kw) | 200 | 315 | 400 | |

| Weight (kg) | 11840 | 16800 | 32000 | |

| Overall Sizes (mm) | 3670*2517*2050 | 3670*2817*2050 | 4360*3150*2200 | |

- Specially designed for round logs, wood slabs, square blocks, wood staff, offcuts.

-

Automatic raw material feeding and continuous chipping technology.

- Easy operation

- Simple maintenance at low cost

- Long working life and low noise

- Drum chipper would be the best choice for chipping wood raw materials.

Operation Video: