Palm EFB Chopping Machine

SIMEC Palm EFB Chopping Machine Running in Thailand

With the fast development of the palm oil industry, throughout Malaysia, Indonesia, Vietnam, South America, Africa and other regions and countries around the world, how to effectively utilise the massive amount of the byproduct palm EFB perplex the owners. As the biomass pellet market booming these years, to convert the palm EFB into biomass pellets has been getting the nod by the oil plant owners and the pellet market. But many investors quit the plan helpless, due to the high cost of the pretreatment of the raw material.

With more than 20 years’ experience in the biomass pellet industry, we have invented the efficient palm EFB chopping machine, which costs less and operates simply.

The palm EFB chopping machine is one key machine of our palm EFB pellet plant with new technology and high processing efficiency. Comparing with the traditional pretreatment to the palm EFB, our palm EFB chopping machine can directly chop the fresh palm EFB with 70% moisture content into 10-50mm fiber without squeezing the liquid out. The chopped fiber could be easily dried and finely crushed in the following palm EFB pellet processing, which guarantees the high quality of the final palm EFB pellets products.

Palm EFB Chopping Machine

Palm EFB Chopper

Palm EFB Chopping Machine

Palm EFB Chopper

Features:

1. Easy Installation

The chopping machine can be simply installed on the hardened and flat floor without any foundation to civil work, which can save the installation cost and move the machine conveniently.

2. Widen Feed Inlet

Thanks for the widened feed inlet, the palm EFB can be fed to the chopping chamber smoothly without blocking and intertwining.

3. High Production Efficiency

With unique designing of the roller and the knife inside of the machine, the lengthened knife roller, enlarged diameter of the roller and the unique arrangement of the knife, the machine can shred the palm EFB from massive to short fiber efficiently;

4. Long Serve Life

The chopping machine shell is made from thick and heavy casting carbon steel, which is very strong and bears the running of the machine. We produce knives and rollers with alloy steel and unique designing, which can chop the palm EFB efficiently and durably.

5. Safety

Thanks for the appliance of the famous brand electrical apparatus elements and the voltage-reduced starting device in the cabinet, the motor can be protected when it starts.

6. Energy Saving

Comparing with the other palm EFB chopping machine, due to the unique designing of the knives and rollers, the palm EFB can be chopped via a 110kw motor driving instead of a 220kw with the same output capacity.

Palm EFB Chopping Machine Test Run

Palm EFB Getting into Chopping Machine

Chopped Palm EFB Fiber

Palm EFB Fiber

Technical Parameters of Palm EFB Chopping Machine:

| Model | BX-G3135D | BX-G216D | BX-G316D | BX-G316D1 | BX-G316D2 | BX-G318D | BX-G318D1 | BX-G318D2 |

| Power | 30kw | 55kw | 55kw | 55kw | 90kw | 132kw | 160kw | 185kw |

| Capacity | 1-3t/h | 6-8t/h | 6-8t/h | 8-10t/h | 10-12t/h | 10-15t/h | 15-18t | 20-25t |

| Feed Inlet Size (mm) | 360*180 | 620*250 | 620*250 | 1100*250 | 1250*250 | 750*300 | 1100*300 | 1300*320 |

| Required EFB Size(mm) | 180 | 500*200 | 500*200 | 500*230 | 500*230 | 650*280 | 650*280 | 650*280 |

| Main shaft Speed | 680rpm | 680rpm | 680rpm | 680rpm | 650rpm | 650rpm | 620rpm | 580rpm |

| Knife Roller Width | 360mm | 600mm | 600mm | 1200mm | 1350mm | 780mm | 1200mm | 1400mm |

| Knife Roller Diameter | 500mm | 650mm | 650mm | 650mm | 650mm | 850mm | 850mm | 850mm |

| Knife Amount | 4pcs | 4pcs | 4pcs | 4pcs | 4pcs | 5pcs | 5*2pcs | 5*2pcs |

|

Overall Size (mm) |

2700*1700 *1300 |

2100*2100 *1250 |

2800*2100 *1550 |

2800*2500 *1600 |

2800*2800 *1700 |

3600*2800 *1900 |

3600*2800 *1900 |

3800*3200 *2000 |

Palm EFB Chopping Machine Test Run Video:

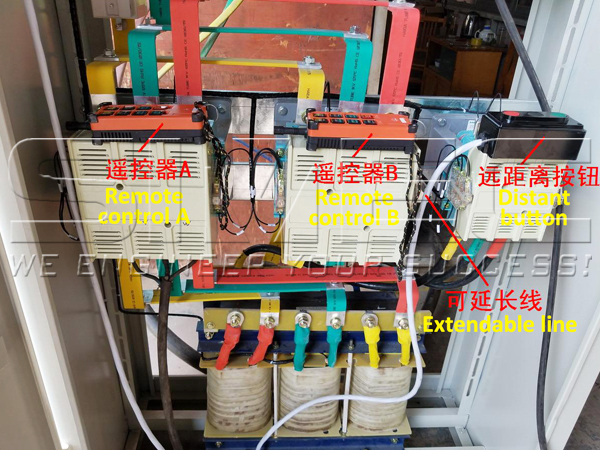

SIMEC palm EFB chopping machine has specially designed electric control system for customers to choose based on their practical production conditions.

Electric Control Cabinet Main Panel Diagram

Remote Controllers of Palm EFB Chopping Machine

There're three control options:

1- To control on the cabinet (this is okay when technician is close to the cabinet)

2- To control by remote controller (this option is necessary when your technician is not in control room, but far from machine)

3- To control by far distant controller (this option can be installed very close to machine, for any urgent operation)

Three control options can make action at the same time. In palm oil mills, there’re often many impurities mixed with palm EFB, such as stones. The linkage control system will contribute to reduce running risks which caused by impurities. It is specially designed by SIMEC R&D team, based on our experience in palm EFB chopping.

Please DOWNLOAD THE ELECTRIC MANUAL to get instructions for detail information and operation methods of the control system.