SPM650 Biomass Pellet Mill

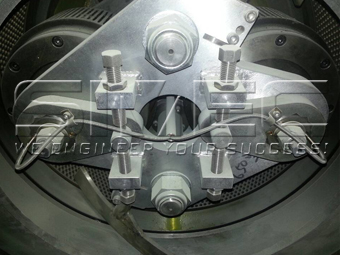

The pelleting chamber door, feeder and conditioner are made of stainless steel. Interlocked roller adjusting system provides fast and reliable adjustment of clearance between rollers and die. Pneumatic quick-dump bypass, overload protection shear pin, die and roller hoist device strongly furnish the users safe operation.

SPM650 Biomass Pellet Mill

Technical data:

| Pellet Mill type | SPM650 |

| Ring Die Inside Diameter | 650 MM |

| Capacity | 2.5-3.0 TPH |

| Roller Quantity | 2 PCS |

| Roller Diameter | 295MM |

| Main Motor Power | 200 KW |

| Conditioner Motor Power | 7.5 KW |

| Screw Feeder Motor Power | 3KW Frequency Conversion Speed Control |

Roller Bearing Temperature Detector

Specification:

- Single motor two-stage reduction driving system;

- synchronized tooth belt driving system will avoid belt slipping;

- Frequency control timing feeder, operation security system;

- Automatic roller bearings temperature detecting and protection system; The innovation will prevent the roller bearings from broken and increase the life span.

- Strong magnetic separator installation, iron impurity can be removed efficiently;

- Force feeding system, water adding system and lost speed detection devices are optional;

- The ring die hoist system can reduce the labor intensity during changing the ring die;

- Automatic lubrication system, which can enlarge the service life of the rollers;

- Main shaft and hollow shaft made of high quality forging part, CNC high precision machining, SKF bearings;

- Automatic Anti-overload Protection system and automatic pneumatic emergency dump device .