The Path to Be A Master of Wood Pellet Produce

I. Production Stages of Biomass Pellet

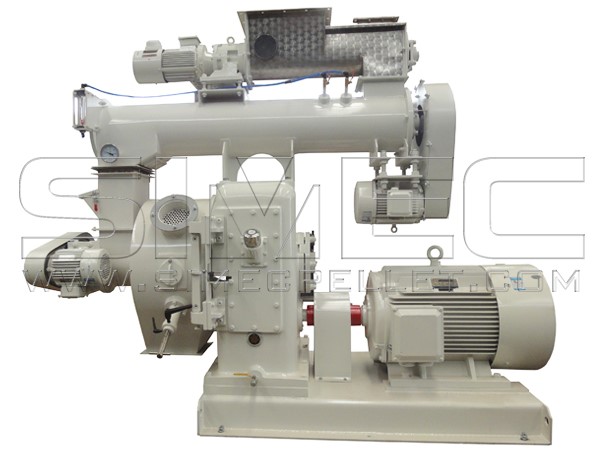

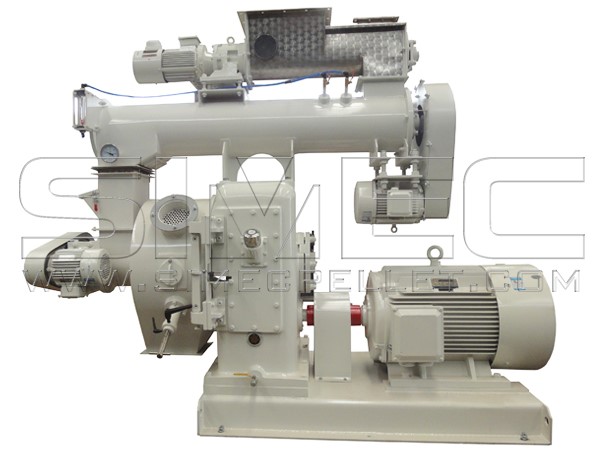

SIMEC devoted to make high quality equipment as well as great customer experience. We will help the customers from the beginning of design the plant, install the equipment till the 100% productivity.

1. Primary Stage (New Customer)

For new customers who begin to produce wood pellets, the first three to four months is the learning period for them to adapt to the production. This period is crucial for the customers to lay a solid foundation for smooth and normal production in the future. There are several important tasks for us to do with new customers:

(1). SIMEC professional installation and commissioning engineers will train all operators of the customers earnestly on the site according to the training scheme to make sure that all the operators can be skilled at the maintenance of pellet mills and auxiliary equipment and be familiar with precautions for operation; it must be stressed that pellet mill can not be forced to produce. The training lasts for one to two weeks.

(2). The customer should arrange suitable preparatory operators in advance to engage in installation and commissioning of equipment so that they can have a perceptual knowledge in advance for improvement of training quality at the initial stage of production. Suitable preparatory operators should include one person with machine maintenance experience and one person with experience of recognizing wood species and moisture. Because raw materials of saw dusts vary, it is often the case that it is hard to granulate during production. In this case, a person with machine maintenance experience will not permit the pellet mill to produce forcibly, lowering the risk to damage the pellet mill enormously. A person with experience of recognizing wood species and moisture can deploy raw materials to make them arrive at the optimal granulation zone fit for granulating to the full. During the period of adjusting to production, we must communicate with customers every two weeks. We know about the actual usage by the operators via telephone (0086 372 5375806), e-mail (info@simecpellet.com) and onsite usage of photos and so on to find existing problems and help and instruct customers to solve the existing problems correctly. During this period, our emphasis is to have operators generally master correct operation and maintenance of equipment and ensure that there is no forcible overloaded production, so that initial stable production can be achieved. Besides, we will make the operator with experience of recognizing timbers grasp the raw material burdening skills preliminarily, making him aware of the importance of raw material burdening. We must make the operator develop the good habit of operating and maintaining.

SIMEC installation and commissioning engineers provide professional train and guide to the customers for proper production, customers can feel free to contact us by phone or email if they have any questions. We are willing to solve your problems.

2. Middle-Level Stage

After three to four months of adaptation to the production, the operator has been armed with some production experience and skills. In the following four months, the main task facing with the customer is to produce persistently around the clock. Operators must cooperate with each other to form an operating team. Each member must realize that unity is strength and share with other team members his own operating experience and skills, with mutual communication to improve each other. The operating team must find the reasonable conditions (11-14% water content in the raw material) for granulator working to reduce the stop rate to the lowest level and realize all-weather consistent production.

(1). Because raw materials differ greatly due to species and non-uniform water content and there is a limited burdening level, the operator shall make the pellet mill to function 80% of the capacity to ensure that the shear pin will not be cut off and that the pellet mill can work continuously.

(2). The operator can promptly discover and solve problems according to such phenomena as electric current change in the electrical machine, change of granulation noise and change of granule quality to guarantee continuous production of high-quality wood granules, and record related operation experience.

(3). Burdening personnel must promptly have knowledge of species and water content of raw materials which are stacked separately. Conduct the burdening four hours ahead of production and continuously sum up experience based on granulation effects, trying to make the assorted raw materials reach the optimal granulation spot. Burdening personnel must sense water content in the raw material of the saw dusts just with his hand. (Record experience data)

(4). The operator must truly comprehend implications of “virtuous circle production” and “vicious circle production”. During production of wood pellet, the more uniform the ingredients are and the more smooth (reaching 100%) ejection of compact is, the less resistance If the ingredients are more uniform and the ejection of compact from the stamper is more smooth (reaching 100%), there will be less resistance during granulating and more smooth production with high granule production yield of high quality, less damage to the equipment and less loss of vulnerable parts. That is called virtuous circle production; otherwise, it is called vicious circle.

SIMEC can provide quality equipment and considerate aftersales services, we can design the pellet plant according to the customers production requirement as well as supply the different models of ring die to satisfy the different raw materials. Choosing the suitable die is important during producing.

3. Senior Stage

If a customer has been the mid-level customer, he can possibly be a senior gold customer. A senor gold customer is characterized with:

(1). The machine operators must be able to prevent the occurrence of all faults to ensure the equipment can produce continuously, stably and effectively. Meanwhile, they must be able to repair and improve the working parts to guarantee the optimal status of production capacity, which prolongs service life of accessories and vulnerable parts greatly and minimizes production cost.

(2). Burdening personnel must be able to deploy raw materials to the optimal granulation spots (raw materials and ingredients are uniform and water content is 11-14%) to ensure the granulator can work stably to the fullest extent.

(3). The gold operating team must ensure a continuous and stable production with 100% full load any time and any where.

II. Experience Sharing of Wood Pellet Production

Customer A:

Manager Wang said that the smaller the compression ratio was, the longer the die’s service life was. After observing old dies that had been used, I found that only 60-70% service life of most dies had been used. The bell-mouth orifices in the working zones of the inner walls of dies were flattened by the dies. Press rolls were fastened too tightly so that they were rubbed against the dies, leading to loss of life service; especially when the saw dusts were cut in the granulation room, the stampers were heavily rubbed against the press rolls, the bearings of the press rolls broke easily. Why do the operators tighten the press rolls? Because they use counterfeit main shaft bearings with big gap which causes the steel fire treated hardness to fail to reach the standard. After two months of working, there is serious abrasion and big gap, so the head of the main shaft will swing to retreat when squeezing the saw dust. In that case, the operators have to tighten the press rolls against the stampers to squeeze out wood pellets. Therefore, high quality bearings of main shafts shall be adopted; meanwhile, in the process of production, it is required to check if the main shaft swings or not on a regular basis. If swinging indeed occurs, inspect if the tooth profile flange matches the main shaft and if the main shaft gland is hanged tightly. Find out causes and solve problems promptly to avoid the swinging of the head of the main shaft.

Customer B:

(1). The operators adjust the gap between the roller and the dies well now just without contact and make the saw dust grind bellmouth orifices of the dies. The bellmouth orifices in the working zones inside the dies are evenly and beautifully worn, and only four bearings of the rollers are damaged within one month. Additionally, when new dies replace the old ones, new rollers also substitute the old ones, thus the working planes of the dies matching that of the rollers well. Operators also mentioned that they once used other manufacturers’ granulators. Due to serious shear pin spline wear and big gap of main shaft bearings, heads of the main shafts swung dramatically. So they had to adjust the press rollers against the dies to squeeze out granules forcibly. Thus, the same bad situation with that of Customer A or even worse situation occurred. Four roller bearing were burned out within a night, more than twice lubricating oil were used and working zones of the dies were severely damaged with bellmouth orifices seriously flattened, leading to worsening ejection of compact from the stampers or even little or no ejection of compact. This indicates the importance of the main shaft matching the safety pin spline fitting and that the heads of the main shaft must not swing. Besides, the Manager mentioned that the heads of the main shafts might swing when ejection of compact was hard to achieve from the discharge holes on both sides of the dies.

(2). One month before, in the test run, when we installed our wide double-headed feeding scarpers in the stamper covers, the saw dust entered the pelletizing chamber directly because they were not smashed and screened (25mm square-mesh screen). The screened sawdust contained numbers of wood shavings and some small wood bricks, which resulted in poor mobility. Therefore, most wide double-headed feeding scarpers remained in the stamper covers and could not enter the blanketed zones, which led to the sharp increase and fluctuation of working current of the granulators. The operator removed one head of the feeding scarper and narrowed the bigger head of the scraper to the width of 30mm, which was installed on the top. In this way, the granulator worked very stably and the capacity increased greatly. The reasons were:①The materials were directly cast into the granulation zone through the blades of the force feeder because there was no small head of the feeding scarper to block the materials at the bottom of the granulation room. ②While the narrowed head of the scraper permitted part of the materials to enter the granulation zone, the rest materials escaped. Based on that, the following improvement suggestions were concluded: ① Because of differing thickness and mobility of sawdust, we provide customers with improved double-headed feeding scrapers and single-headed feeding scrapers to facilitate their use. ② Use a force feeder and take the full advantage of its blades to push so that it can feed the materials evenly into the upper and lower granulation zones to the full.

(3). For the raw materials zone is not big, the raw material burdening is not practical, which causes the raw materials to be dry sometimes and to be wet other times; consequently, the granules quality and production conditions of the granulator are not steady.

Customer C

(1). Four sets of SPM420 pellet mills form one production line. The granule in the stock bin near the feeding port is smaller, and the compression ratio of die could be a little higher. The farther the stock bin is, the bigger the granule is. And the compression ratio of dies could be a little lower. Besides, the compression ration could be a litter lower if their wood is dry.

(2). Ingredient production is allowed when their raw material storage is enough. They put some larch wood chips easy to granulate into the feeding port, so it is easier to granulate when larch wood chips is mixed into other chips which are hard to granulate.

Customer D

(1). The production efficiency of SPM420 wood pellet machine of Plant Manager Song normally performs to its maximum (1.2-1.3t/h, the currency of ∮10mm granule main motor current is 170-190Am ). He thinks the only way to reduce production cost is to increase production. (Labor wages are about 40 yuan/tons of granule, while the wage of B customer is about 70 yuan/tons of granule).

(2). Production pattern: Repair and maintain equipment and allocate raw material in the daytime. Carry out full production at night.

(3). Plant Manager Song shall personally check the granulators every morning.

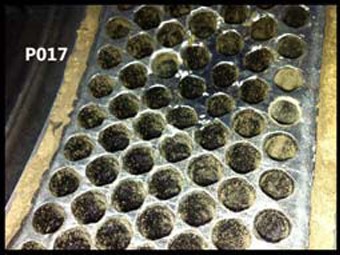

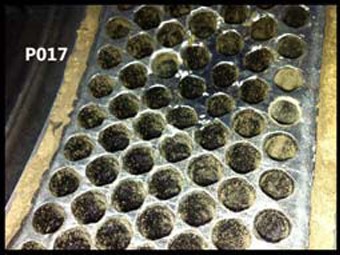

Check the discharge situation of compressing mould. Use the large diameter bit of hammers and electric hammers to punch the clogged hole in iron or cement clinker to guarantee every hole is discharging. He said that if there are three holes failing to discharge, 120kg granule production is decreased; in addition, if the clogged hole is not cleaned, the chip is not worn, then the salient clogged hole would draw a circle groove in the contact surface of compression roller after a long time. It influences die hole discharge of one week. Therefore, we must guarantee all holes are discharging. It is necessary for smooth production and high capacity. Besides, fuel fills up the new press machine when it is power-off during one week. After that, when the machine normally and smoothly works, it is not filled with fuel. We just need clean the hole every day.

(4). After the new pellet machine works for two hours, die clamp screw may be loose, so the machine shall be power-off and tighten the screw again; then the hoop would not loose at work. Otherwise, die clamp would loose and damage quill shaft and die. And die is easy to crack.

(5). He also checks the degree of tightness of all kinds screws (especially the clamp screw in main shaft and die clamp screw), the loose situation of safety housing, and the mismatch situation of shear pin. If the screw is found damaged, it shall be replaced in advance to prevent hoop press mould and face plate is damaged because of the breakage of screw. Prevention and maintenance are very important.

(6). As for Φ10 mm press mould, he suggests using open rough tooth die because it feeds more material and discharge faster. If close rough tooth compression roller is used, the working current fluctuates a lot sometimes. As for Φ6.0 and Φ8.0 mm small hole dies, he suggests using close minute tooth dies because it feeds litter material and discharge slower. When roller is damaged and groove in working surface becomes shallow, the feeding reduces. After he uses the polisher to make the groove deeper, the feeding of roller increases.

(7). Batching is one of the most important steps to produce the wood pellet. At the time of batching, the moisture of raw material shall be controlled in 11% to 14% to guarantee that pellet mills are in full production every day. He appoints the feeding driver to unload and stack the different raw materials according to their classification; hard wood into one pile, the wet wood chip high than 17% moisture into one pile and the dry bamboo chip easy to granulate and mix stacked near the wall. Then he uses forklifts to mix the different raw materials according to its moisture, fineness and hardness; when the raw material is too dry, the wet material is mixed into it. The hard wood ship is mixed with soft wood ship. The thick material is mixed with thin material. Strive to guarantee the moisture of the mixture is in 11-14%. Under this condition, the granulating production is smooth. The granulator works stably, the electrical machine performs 100% efficiency. The quality of wood pellet is good and the quantity of it is high. If the operation staff finds out that some material granulates badly and the shape of the granule is not good, he can add some bamboo ship or larch (with good oilness, slim and long) into the ship to make granules have a good shape.

(8). If the feeding wood chip into the pellet mill is too wet, the voice of granulator will deepen; if the feeding wood chip into the pellet mill is too dry, the pellet mill will produce short and loud voice because the short and hard wood chip strikes its face plate. If the moisture of the feeding wood ship into the granulator is appropriate (11-14%), the voice of the granulator is clear and pleasant. We can judge the moisture of the raw material according to above voice.

(9). When the moisture and uniformity of the raw material is appropriate, without severe impact caused by woods or metals entering into the pellet machine, in full production or even in overload production, the shear pin is not easy to break as long as the feeding is stable.

Customer E

(1). The two sides of dies workspace of SPM520 pellet mill shall be deeper, so the gap of die and roller on both sides is bigger and the sawdust in the middle could avoid to be compressed. And the pressure of roller in workspace could be reduced; otherwise, in the middle and latter periods, the die would lose some pressure on both compression areas and becomes hard to pellet and the working current would fluctuate for it is filled with compressed wood chip and the gap is too small.

(2). When some compression holes are clogged, especially the clogged holes distributed in different places, current fluctuates more drastically. Therefore, when we observed that current fluctuation is abnormal, some compression holes may have already been clogged. The clogged holes shall be cleaned. It is better to replace the die and completely clean the clogged hole. Use two or three dies in turn to guarantee it is in full production.

(3). When working current fluctuation of pellet is drastic the bearing inside roller may be damaged. When operation staffs start the no-load machine every morning, he shall judge whether the bearing is damaged or not through listening to the running sound of roller or checking whether the shaft collar becomes blue or observing the color of lubricating oil. The operation staff shall record the life span of roller bearing. On the basis of this experience, the damaged bearing shall be replaced in advance two or three days before it is to be damaged. Therefore roller and gland oil thrower can avoid to be pressed out of shape and they can be reused many times. The cost is greatly saved; otherwise, when the bearing is damaged, roller, shaft collar and seal collar would be pressed out of shape and no longer reused.

(4). A high-temperature insulation “O” shaped circle (¢70*3.1 mm) shall be put on the spindle head of the SPM520 roller shaft. In a certain degree it can prevent lubricating grease leaking from the gap between the spindle head and the damaged bush, instead of being infused into the roller, causing the bearing burning because of fuel starvation.

(5). The working current of SPM520 pellet mill shall be controlled within 180-200 Am. Under this condition, the operation is stable; the shear pin is not easy to break; and continuous production efficiency is high.

(6). The gap between the die and roller is as small as possible but can not touch. Roller can provide largest pressure without damaging the inwall of die and its life span is the longest under this condition. The method to specifically adjust the gap is using hands to turn the press mould, with compression roller moving sometimes. Then loosen the adjustment screw 0.5-1 circle to increase the gap a little to prevent the friction between die and roller. Of course, as for sawdust which is hard to compress, the gap shall be smaller. The adjustment scope is about 10%. The operation staff shall observe wear pattern of inwall of the die and adjust the gap specifically. Remember that the operation staff must guarantee that what the wood ship wears is the horn hole of the die, not the roller.

(7). When new die is put into use, it needs new roller. During the first week, the operation staff shall clean the clogged hole before it is power-on to guarantee every hole is discharging. After the die works for 1-2 weeks, the operation staff shall observe whether the damage in both sides of die workspace is uniform. If the operation staff observes that rows of outside holes wear less, the gap between the outside holes and the feeding scraper shall be enlarged or the feeding scraper shall be shortened to make more wood chip enters this rows of holes; if the operation staff observes that rows of inside holes wear less, the feeding scraper shall be lengthened to make more wood ship enter inside. In short, the operation staff must guarantee the damage in both sides of die workspace is uniform. In addition, the operation staff shall also try their best to guarantee the damage in right and the left compression roller is uniform.

To sum up, customer D and customer E are senior gold customers with full production. They can perform wood pellet mill’s 100% productivity.

SIMEC devotes to make higher quality device as well as better customer experience. From the installation and normal producing, we are pleased to provide opinions and suggestions to customers for 100% productivity.

For more information, please contact SIMEC.

Email: info@simecpellet.com

Tel: +86 372 5375806

*Copyright of the contents and photos in this brochure belongs to SIMEC.

*We reserve the right to make changes in technical aspects, material and specifications without prior notice.

SIMEC devoted to make high quality equipment as well as great customer experience. We will help the customers from the beginning of design the plant, install the equipment till the 100% productivity.

1. Primary Stage (New Customer)

For new customers who begin to produce wood pellets, the first three to four months is the learning period for them to adapt to the production. This period is crucial for the customers to lay a solid foundation for smooth and normal production in the future. There are several important tasks for us to do with new customers:

(1). SIMEC professional installation and commissioning engineers will train all operators of the customers earnestly on the site according to the training scheme to make sure that all the operators can be skilled at the maintenance of pellet mills and auxiliary equipment and be familiar with precautions for operation; it must be stressed that pellet mill can not be forced to produce. The training lasts for one to two weeks.

(2). The customer should arrange suitable preparatory operators in advance to engage in installation and commissioning of equipment so that they can have a perceptual knowledge in advance for improvement of training quality at the initial stage of production. Suitable preparatory operators should include one person with machine maintenance experience and one person with experience of recognizing wood species and moisture. Because raw materials of saw dusts vary, it is often the case that it is hard to granulate during production. In this case, a person with machine maintenance experience will not permit the pellet mill to produce forcibly, lowering the risk to damage the pellet mill enormously. A person with experience of recognizing wood species and moisture can deploy raw materials to make them arrive at the optimal granulation zone fit for granulating to the full. During the period of adjusting to production, we must communicate with customers every two weeks. We know about the actual usage by the operators via telephone (0086 372 5375806), e-mail (info@simecpellet.com) and onsite usage of photos and so on to find existing problems and help and instruct customers to solve the existing problems correctly. During this period, our emphasis is to have operators generally master correct operation and maintenance of equipment and ensure that there is no forcible overloaded production, so that initial stable production can be achieved. Besides, we will make the operator with experience of recognizing timbers grasp the raw material burdening skills preliminarily, making him aware of the importance of raw material burdening. We must make the operator develop the good habit of operating and maintaining.

SIMEC installation and commissioning engineers provide professional train and guide to the customers for proper production, customers can feel free to contact us by phone or email if they have any questions. We are willing to solve your problems.

2. Middle-Level Stage

After three to four months of adaptation to the production, the operator has been armed with some production experience and skills. In the following four months, the main task facing with the customer is to produce persistently around the clock. Operators must cooperate with each other to form an operating team. Each member must realize that unity is strength and share with other team members his own operating experience and skills, with mutual communication to improve each other. The operating team must find the reasonable conditions (11-14% water content in the raw material) for granulator working to reduce the stop rate to the lowest level and realize all-weather consistent production.

(1). Because raw materials differ greatly due to species and non-uniform water content and there is a limited burdening level, the operator shall make the pellet mill to function 80% of the capacity to ensure that the shear pin will not be cut off and that the pellet mill can work continuously.

(2). The operator can promptly discover and solve problems according to such phenomena as electric current change in the electrical machine, change of granulation noise and change of granule quality to guarantee continuous production of high-quality wood granules, and record related operation experience.

(3). Burdening personnel must promptly have knowledge of species and water content of raw materials which are stacked separately. Conduct the burdening four hours ahead of production and continuously sum up experience based on granulation effects, trying to make the assorted raw materials reach the optimal granulation spot. Burdening personnel must sense water content in the raw material of the saw dusts just with his hand. (Record experience data)

(4). The operator must truly comprehend implications of “virtuous circle production” and “vicious circle production”. During production of wood pellet, the more uniform the ingredients are and the more smooth (reaching 100%) ejection of compact is, the less resistance If the ingredients are more uniform and the ejection of compact from the stamper is more smooth (reaching 100%), there will be less resistance during granulating and more smooth production with high granule production yield of high quality, less damage to the equipment and less loss of vulnerable parts. That is called virtuous circle production; otherwise, it is called vicious circle.

SIMEC can provide quality equipment and considerate aftersales services, we can design the pellet plant according to the customers production requirement as well as supply the different models of ring die to satisfy the different raw materials. Choosing the suitable die is important during producing.

3. Senior Stage

If a customer has been the mid-level customer, he can possibly be a senior gold customer. A senor gold customer is characterized with:

(1). The machine operators must be able to prevent the occurrence of all faults to ensure the equipment can produce continuously, stably and effectively. Meanwhile, they must be able to repair and improve the working parts to guarantee the optimal status of production capacity, which prolongs service life of accessories and vulnerable parts greatly and minimizes production cost.

(2). Burdening personnel must be able to deploy raw materials to the optimal granulation spots (raw materials and ingredients are uniform and water content is 11-14%) to ensure the granulator can work stably to the fullest extent.

(3). The gold operating team must ensure a continuous and stable production with 100% full load any time and any where.

II. Experience Sharing of Wood Pellet Production

Customer A:

Manager Wang said that the smaller the compression ratio was, the longer the die’s service life was. After observing old dies that had been used, I found that only 60-70% service life of most dies had been used. The bell-mouth orifices in the working zones of the inner walls of dies were flattened by the dies. Press rolls were fastened too tightly so that they were rubbed against the dies, leading to loss of life service; especially when the saw dusts were cut in the granulation room, the stampers were heavily rubbed against the press rolls, the bearings of the press rolls broke easily. Why do the operators tighten the press rolls? Because they use counterfeit main shaft bearings with big gap which causes the steel fire treated hardness to fail to reach the standard. After two months of working, there is serious abrasion and big gap, so the head of the main shaft will swing to retreat when squeezing the saw dust. In that case, the operators have to tighten the press rolls against the stampers to squeeze out wood pellets. Therefore, high quality bearings of main shafts shall be adopted; meanwhile, in the process of production, it is required to check if the main shaft swings or not on a regular basis. If swinging indeed occurs, inspect if the tooth profile flange matches the main shaft and if the main shaft gland is hanged tightly. Find out causes and solve problems promptly to avoid the swinging of the head of the main shaft.

(1). The operators adjust the gap between the roller and the dies well now just without contact and make the saw dust grind bellmouth orifices of the dies. The bellmouth orifices in the working zones inside the dies are evenly and beautifully worn, and only four bearings of the rollers are damaged within one month. Additionally, when new dies replace the old ones, new rollers also substitute the old ones, thus the working planes of the dies matching that of the rollers well. Operators also mentioned that they once used other manufacturers’ granulators. Due to serious shear pin spline wear and big gap of main shaft bearings, heads of the main shafts swung dramatically. So they had to adjust the press rollers against the dies to squeeze out granules forcibly. Thus, the same bad situation with that of Customer A or even worse situation occurred. Four roller bearing were burned out within a night, more than twice lubricating oil were used and working zones of the dies were severely damaged with bellmouth orifices seriously flattened, leading to worsening ejection of compact from the stampers or even little or no ejection of compact. This indicates the importance of the main shaft matching the safety pin spline fitting and that the heads of the main shaft must not swing. Besides, the Manager mentioned that the heads of the main shafts might swing when ejection of compact was hard to achieve from the discharge holes on both sides of the dies.

(2). One month before, in the test run, when we installed our wide double-headed feeding scarpers in the stamper covers, the saw dust entered the pelletizing chamber directly because they were not smashed and screened (25mm square-mesh screen). The screened sawdust contained numbers of wood shavings and some small wood bricks, which resulted in poor mobility. Therefore, most wide double-headed feeding scarpers remained in the stamper covers and could not enter the blanketed zones, which led to the sharp increase and fluctuation of working current of the granulators. The operator removed one head of the feeding scarper and narrowed the bigger head of the scraper to the width of 30mm, which was installed on the top. In this way, the granulator worked very stably and the capacity increased greatly. The reasons were:①The materials were directly cast into the granulation zone through the blades of the force feeder because there was no small head of the feeding scarper to block the materials at the bottom of the granulation room. ②While the narrowed head of the scraper permitted part of the materials to enter the granulation zone, the rest materials escaped. Based on that, the following improvement suggestions were concluded: ① Because of differing thickness and mobility of sawdust, we provide customers with improved double-headed feeding scrapers and single-headed feeding scrapers to facilitate their use. ② Use a force feeder and take the full advantage of its blades to push so that it can feed the materials evenly into the upper and lower granulation zones to the full.

(3). For the raw materials zone is not big, the raw material burdening is not practical, which causes the raw materials to be dry sometimes and to be wet other times; consequently, the granules quality and production conditions of the granulator are not steady.

(1). Four sets of SPM420 pellet mills form one production line. The granule in the stock bin near the feeding port is smaller, and the compression ratio of die could be a little higher. The farther the stock bin is, the bigger the granule is. And the compression ratio of dies could be a little lower. Besides, the compression ration could be a litter lower if their wood is dry.

(2). Ingredient production is allowed when their raw material storage is enough. They put some larch wood chips easy to granulate into the feeding port, so it is easier to granulate when larch wood chips is mixed into other chips which are hard to granulate.

Customer D

(1). The production efficiency of SPM420 wood pellet machine of Plant Manager Song normally performs to its maximum (1.2-1.3t/h, the currency of ∮10mm granule main motor current is 170-190Am ). He thinks the only way to reduce production cost is to increase production. (Labor wages are about 40 yuan/tons of granule, while the wage of B customer is about 70 yuan/tons of granule).

(2). Production pattern: Repair and maintain equipment and allocate raw material in the daytime. Carry out full production at night.

(3). Plant Manager Song shall personally check the granulators every morning.

Check the discharge situation of compressing mould. Use the large diameter bit of hammers and electric hammers to punch the clogged hole in iron or cement clinker to guarantee every hole is discharging. He said that if there are three holes failing to discharge, 120kg granule production is decreased; in addition, if the clogged hole is not cleaned, the chip is not worn, then the salient clogged hole would draw a circle groove in the contact surface of compression roller after a long time. It influences die hole discharge of one week. Therefore, we must guarantee all holes are discharging. It is necessary for smooth production and high capacity. Besides, fuel fills up the new press machine when it is power-off during one week. After that, when the machine normally and smoothly works, it is not filled with fuel. We just need clean the hole every day.

(4). After the new pellet machine works for two hours, die clamp screw may be loose, so the machine shall be power-off and tighten the screw again; then the hoop would not loose at work. Otherwise, die clamp would loose and damage quill shaft and die. And die is easy to crack.

(5). He also checks the degree of tightness of all kinds screws (especially the clamp screw in main shaft and die clamp screw), the loose situation of safety housing, and the mismatch situation of shear pin. If the screw is found damaged, it shall be replaced in advance to prevent hoop press mould and face plate is damaged because of the breakage of screw. Prevention and maintenance are very important.

(6). As for Φ10 mm press mould, he suggests using open rough tooth die because it feeds more material and discharge faster. If close rough tooth compression roller is used, the working current fluctuates a lot sometimes. As for Φ6.0 and Φ8.0 mm small hole dies, he suggests using close minute tooth dies because it feeds litter material and discharge slower. When roller is damaged and groove in working surface becomes shallow, the feeding reduces. After he uses the polisher to make the groove deeper, the feeding of roller increases.

(7). Batching is one of the most important steps to produce the wood pellet. At the time of batching, the moisture of raw material shall be controlled in 11% to 14% to guarantee that pellet mills are in full production every day. He appoints the feeding driver to unload and stack the different raw materials according to their classification; hard wood into one pile, the wet wood chip high than 17% moisture into one pile and the dry bamboo chip easy to granulate and mix stacked near the wall. Then he uses forklifts to mix the different raw materials according to its moisture, fineness and hardness; when the raw material is too dry, the wet material is mixed into it. The hard wood ship is mixed with soft wood ship. The thick material is mixed with thin material. Strive to guarantee the moisture of the mixture is in 11-14%. Under this condition, the granulating production is smooth. The granulator works stably, the electrical machine performs 100% efficiency. The quality of wood pellet is good and the quantity of it is high. If the operation staff finds out that some material granulates badly and the shape of the granule is not good, he can add some bamboo ship or larch (with good oilness, slim and long) into the ship to make granules have a good shape.

(8). If the feeding wood chip into the pellet mill is too wet, the voice of granulator will deepen; if the feeding wood chip into the pellet mill is too dry, the pellet mill will produce short and loud voice because the short and hard wood chip strikes its face plate. If the moisture of the feeding wood ship into the granulator is appropriate (11-14%), the voice of the granulator is clear and pleasant. We can judge the moisture of the raw material according to above voice.

(9). When the moisture and uniformity of the raw material is appropriate, without severe impact caused by woods or metals entering into the pellet machine, in full production or even in overload production, the shear pin is not easy to break as long as the feeding is stable.

(1). The two sides of dies workspace of SPM520 pellet mill shall be deeper, so the gap of die and roller on both sides is bigger and the sawdust in the middle could avoid to be compressed. And the pressure of roller in workspace could be reduced; otherwise, in the middle and latter periods, the die would lose some pressure on both compression areas and becomes hard to pellet and the working current would fluctuate for it is filled with compressed wood chip and the gap is too small.

(2). When some compression holes are clogged, especially the clogged holes distributed in different places, current fluctuates more drastically. Therefore, when we observed that current fluctuation is abnormal, some compression holes may have already been clogged. The clogged holes shall be cleaned. It is better to replace the die and completely clean the clogged hole. Use two or three dies in turn to guarantee it is in full production.

(3). When working current fluctuation of pellet is drastic the bearing inside roller may be damaged. When operation staffs start the no-load machine every morning, he shall judge whether the bearing is damaged or not through listening to the running sound of roller or checking whether the shaft collar becomes blue or observing the color of lubricating oil. The operation staff shall record the life span of roller bearing. On the basis of this experience, the damaged bearing shall be replaced in advance two or three days before it is to be damaged. Therefore roller and gland oil thrower can avoid to be pressed out of shape and they can be reused many times. The cost is greatly saved; otherwise, when the bearing is damaged, roller, shaft collar and seal collar would be pressed out of shape and no longer reused.

(4). A high-temperature insulation “O” shaped circle (¢70*3.1 mm) shall be put on the spindle head of the SPM520 roller shaft. In a certain degree it can prevent lubricating grease leaking from the gap between the spindle head and the damaged bush, instead of being infused into the roller, causing the bearing burning because of fuel starvation.

(5). The working current of SPM520 pellet mill shall be controlled within 180-200 Am. Under this condition, the operation is stable; the shear pin is not easy to break; and continuous production efficiency is high.

(6). The gap between the die and roller is as small as possible but can not touch. Roller can provide largest pressure without damaging the inwall of die and its life span is the longest under this condition. The method to specifically adjust the gap is using hands to turn the press mould, with compression roller moving sometimes. Then loosen the adjustment screw 0.5-1 circle to increase the gap a little to prevent the friction between die and roller. Of course, as for sawdust which is hard to compress, the gap shall be smaller. The adjustment scope is about 10%. The operation staff shall observe wear pattern of inwall of the die and adjust the gap specifically. Remember that the operation staff must guarantee that what the wood ship wears is the horn hole of the die, not the roller.

(7). When new die is put into use, it needs new roller. During the first week, the operation staff shall clean the clogged hole before it is power-on to guarantee every hole is discharging. After the die works for 1-2 weeks, the operation staff shall observe whether the damage in both sides of die workspace is uniform. If the operation staff observes that rows of outside holes wear less, the gap between the outside holes and the feeding scraper shall be enlarged or the feeding scraper shall be shortened to make more wood chip enters this rows of holes; if the operation staff observes that rows of inside holes wear less, the feeding scraper shall be lengthened to make more wood ship enter inside. In short, the operation staff must guarantee the damage in both sides of die workspace is uniform. In addition, the operation staff shall also try their best to guarantee the damage in right and the left compression roller is uniform.

To sum up, customer D and customer E are senior gold customers with full production. They can perform wood pellet mill’s 100% productivity.

SIMEC devotes to make higher quality device as well as better customer experience. From the installation and normal producing, we are pleased to provide opinions and suggestions to customers for 100% productivity.

For more information, please contact SIMEC.

Email: info@simecpellet.com

Tel: +86 372 5375806

*Copyright of the contents and photos in this brochure belongs to SIMEC.

*We reserve the right to make changes in technical aspects, material and specifications without prior notice.