Vibrating Screen Serves Wood Pellet Facility in Costa Rica

In the wood pellet industry, the precision and efficiency of material screening directly impact product quality. SIMEC SFJZ125 wood pellet vibrating screen, equipped with high-performance vibrating motors and stainless steel screen, quickly and accurately classifies qualified wood pellets, crushed particles, and dust, significantly enhancing screening efficiency. This ensures consistent screening results, meeting the high standard of production demand.

The design of SFJZ125 vibrating screen is simple and efficient, and the streamlined structure makes the operation more intuitive and reduces the complexity of maintenance, thus reducing the possibility of faults. This ease of maintenance ensures that the equipment remains stable even in non-stop operation all year round.

In the field of energy efficiency, the SFJZ125 vibrating screen is excellent, and its core advantage is its integration of two 0.37 kW high-efficiency vibration motors. These motors achieve a significant reduction in energy consumption during operation, directly reducing operating costs and effectively reducing the environmental burden. With its low energy consumption characteristics, SFJZ125 has become a model choice for integrating environmental protection and economic benefits, showing the cutting-edge trend of green development of industrial equipment.

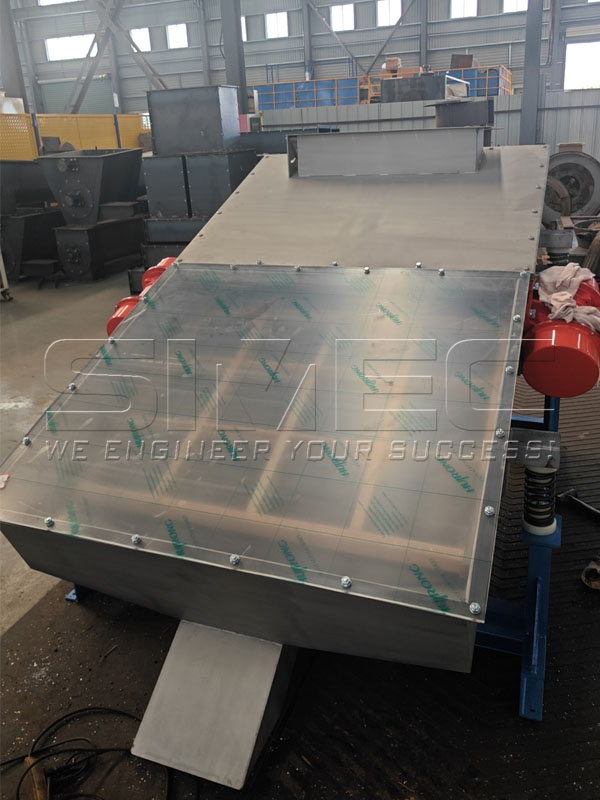

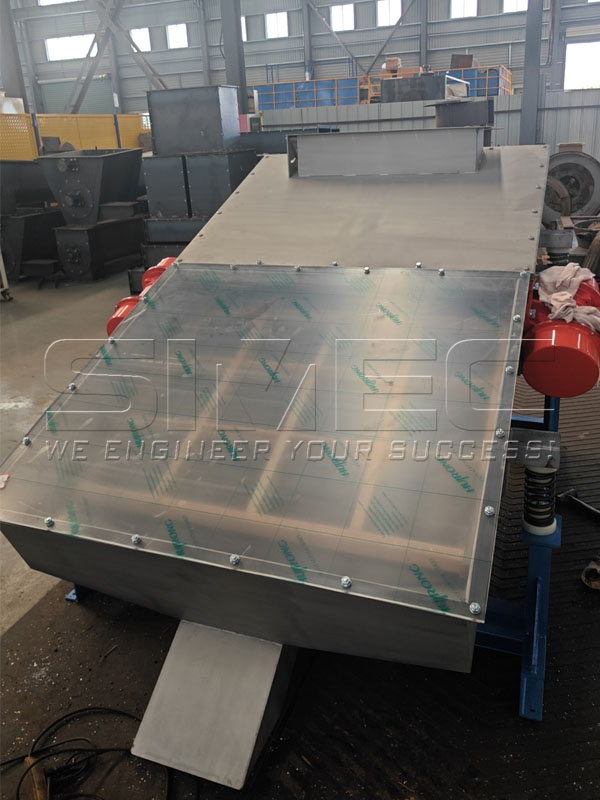

Durability is a highlight of SFJZ125 vibrating screen, featuring a high-quality stainless steel screen body and screen, with a sandblasted surface to enhance corrosion resistance and durability, ensuring long operation in harsh environments. This design reduces the frequency of replacement and improves the long-term investment efficiency, while retaining the original color of stainless steel, which is aesthetically pleasing and durable.

The fully enclosed design is another feature of SFJZ125 vibrating screen. Effectively reduce the dust flying during the screening process, both environmentally friendly and easy to recycle materials. The lower part of the screen body adopts a transparent cover, which allows direct observation of screening effect. This design reflects our commitment to environmental protection, and improves the convenience of production management.

SIMEC wood pellet vibrating screen boasts features of easy cleaning and maintenance, ensuring a streamlined and efficient maintenance process. This design fully considers the practical needs of operators, ensuring the long-term stable operation of the equipment. Additionally, we have carefully planned the packaging and transportation of the equipment to guarantee its safe arrival in Costa Rica. We are confident that SIMEC vibrating screen will demonstrate exceptional performance, bringing unparalleled production optimization experience to our customer.

Packing List:

Delivery Photos:

In the field of energy efficiency, the SFJZ125 vibrating screen is excellent, and its core advantage is its integration of two 0.37 kW high-efficiency vibration motors. These motors achieve a significant reduction in energy consumption during operation, directly reducing operating costs and effectively reducing the environmental burden. With its low energy consumption characteristics, SFJZ125 has become a model choice for integrating environmental protection and economic benefits, showing the cutting-edge trend of green development of industrial equipment.

Durability is a highlight of SFJZ125 vibrating screen, featuring a high-quality stainless steel screen body and screen, with a sandblasted surface to enhance corrosion resistance and durability, ensuring long operation in harsh environments. This design reduces the frequency of replacement and improves the long-term investment efficiency, while retaining the original color of stainless steel, which is aesthetically pleasing and durable.

The fully enclosed design is another feature of SFJZ125 vibrating screen. Effectively reduce the dust flying during the screening process, both environmentally friendly and easy to recycle materials. The lower part of the screen body adopts a transparent cover, which allows direct observation of screening effect. This design reflects our commitment to environmental protection, and improves the convenience of production management.

SIMEC wood pellet vibrating screen boasts features of easy cleaning and maintenance, ensuring a streamlined and efficient maintenance process. This design fully considers the practical needs of operators, ensuring the long-term stable operation of the equipment. Additionally, we have carefully planned the packaging and transportation of the equipment to guarantee its safe arrival in Costa Rica. We are confident that SIMEC vibrating screen will demonstrate exceptional performance, bringing unparalleled production optimization experience to our customer.

We eagerly anticipate future collaborations for a brighter future. Reach out to us promptly at info@simecpellet.com.

Packing List:

| No. | Name | Overall Size | Gross Weight |

| 1 | SFJZ125 Wood Pellet Vibrating Screen | 2350*2050*1750 mm | 820 kgs |

| Total Amount | 8.43 CBM | 820 kgs |

Delivery Photos: