Drum Chipper Delivered to MDF Producer in India

Since its establishment in 1990, SIMEC has been committed to excellence and integrating professional skills with innovative design, becoming the preferred partner for customers globally. The company is committed to fostering a deep connection with its customers by emphasizing design and experience.

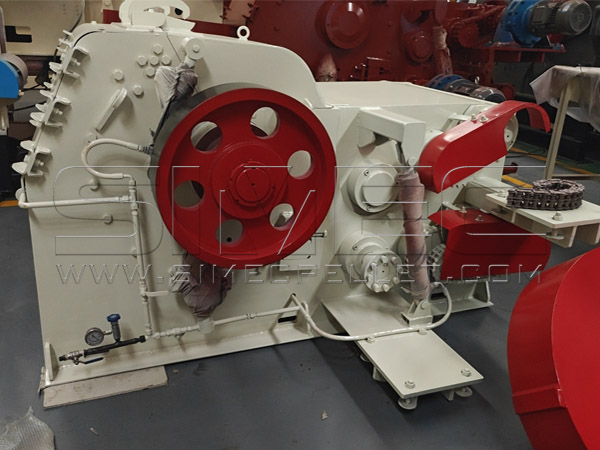

In October 2024, SIMEC's innovative drum chipper and supporting equipment were successfully delivered to a customer in India, marking another important milestone for SIMEC in the international market. The customer is a leading laminate and medium density fiberboard (MDF) manufacturer in India with operations in 53 countries and regions worldwide.

The delivery of SIMEC wood chipping system to the Indian client reflects a mutual dedication to advancing technological innovation and ensuring product excellence shared by both companies, thereby exemplifying their dedication to sustainable progress. Mr. Bhavin Patel, the project director representing the Indian client, remarked, " This investment helps us to gradually achieve our expansion plan of increasing annual production by 55,000 tons through equipment and process improvements; it also supports our company's adherence to the MAP 2030 sustainable development commitment, which aids in cost reduction and efficiency, achieves refined production, and simultaneously improves environmental performance."

In October 2024, SIMEC's innovative drum chipper and supporting equipment were successfully delivered to a customer in India, marking another important milestone for SIMEC in the international market. The customer is a leading laminate and medium density fiberboard (MDF) manufacturer in India with operations in 53 countries and regions worldwide.

The delivery of SIMEC wood chipping system to the Indian client reflects a mutual dedication to advancing technological innovation and ensuring product excellence shared by both companies, thereby exemplifying their dedication to sustainable progress. Mr. Bhavin Patel, the project director representing the Indian client, remarked, " This investment helps us to gradually achieve our expansion plan of increasing annual production by 55,000 tons through equipment and process improvements; it also supports our company's adherence to the MAP 2030 sustainable development commitment, which aids in cost reduction and efficiency, achieves refined production, and simultaneously improves environmental performance."

SIMEC wood chip machine incorporates state-of-the-art chipping technology to process a diverse range of woody materials with consistency, yielding uniformly sized, thinner wood chips, thereby further decreasing energy consumption during the board pressing process. SIMEC wood chipping technology finds extensive application in the material pretreatment process of laminate and MDF production.

In total 7 packages of 1 set of drum chipper, were loaded into 40’ high cube container. HS Code: 8465960000. The cargos left Qingdao port on 11th October 2024, and sailed to Mundra port, India. Packing detail of cargos was listed below:

| No. | Name of Cargos | Overall Dimensions (mm) | Gross Weight(kg) |

| 1 | Control cabinet | 740*520*1900 | 112 |

| 2 | BX218 drum chipper | 2200*1950*1850 | 5000 |

| 3 | Feeding chute | 2100*1000*1200 | 480 |

| 4 | Main driven motor, 132kw | 1300*680*650 | 940 |

| 5 | Feeding conveyor, hydraulic station, spare knives. | 1250*840*800 | 100 |

| 6 | Motors of feeding rollers, tool kit. | 1050*730*660 | 650 |

| 7 | Discharging conveyor | 3600*2100*1600 | 1400 |

| Total amount | 25.20 m3 | 8682 kg |