Ultra-Micro Pulverizer For Ferric Oxide Powder Production

“Ferric Oxide” or “Iron Oxide”, its chemical formula is known as Fe2O3, can be obtained from nature or artificially synthesized. The powder of it can be processed into iron oxide pigments that are nontoxic, nonbleeding, weather resistant, corrosion resistance and lightfast. Colorful iron oxide based pigments can be produced from ferric oxide fine powder, and mainly used for painting, building materials, plastic rubber, ceramics, water-based color paste,and building surface painting materials etc.

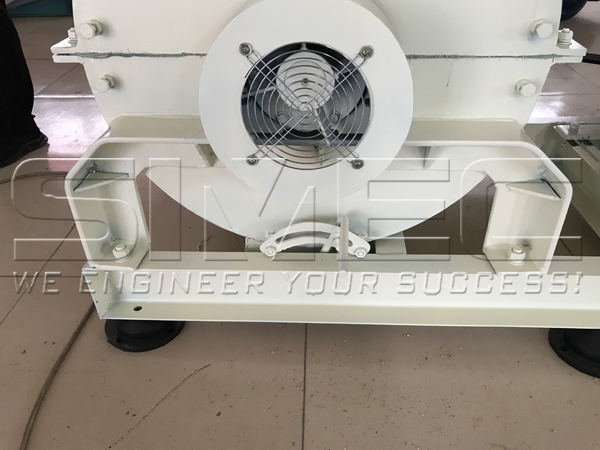

Ultra-Micro Pulverizer is equipped with ingenious water cooling system which can take away most of the heat generated in production and keep the pulverizing mechanism in a normal temperature range.

As another highlight design, the screenless pulverizing mechanism greatly enhances the applicability to a very wider range of raw materials, even if some-high moisture raw materials can be pulverized.

The SIMEC Ultra-micro Pulverizer has been shipped to LIMASSOL PORT, CYPRUS on September 4, 2019. The pulverizer was wrapped with plastic film and packed into 3 plywood cases. The customer also ordered an additional set of spare parts for backup.

Packing Details:

| No. | Name |

Overall Size (mm) |

Gross Weight (kg) |

| 1 | Main body of pulverizer, motor, bracket of airlock, dampers*6, water pipes*3, belt cover*1, long straight pipe*1; | 1700*1100*1020 | 760 |

| 2 | Dust separator, Control Cabinet*1, Air lock *1, V-belt*4, seal washer*20, bolts; | 1700*1100*1270 | 290 |

| 3 | Cyclone*1, Bend pipes*3, Hopper*1, Dust bags*20, bracket for motor, knives*2 sets, discharging bucket*2 | 2450*960*920 | 300 |

| Total | 1350 |