Rotary Dryer Delivery to Poland

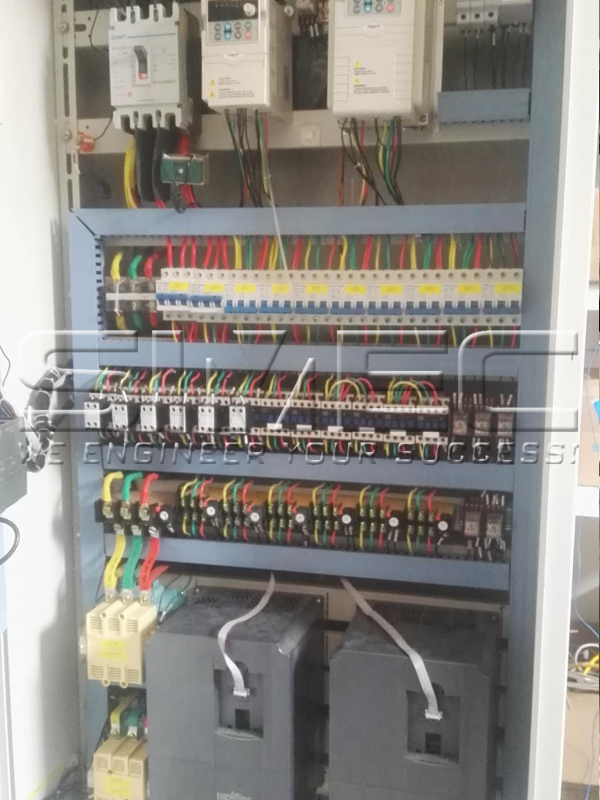

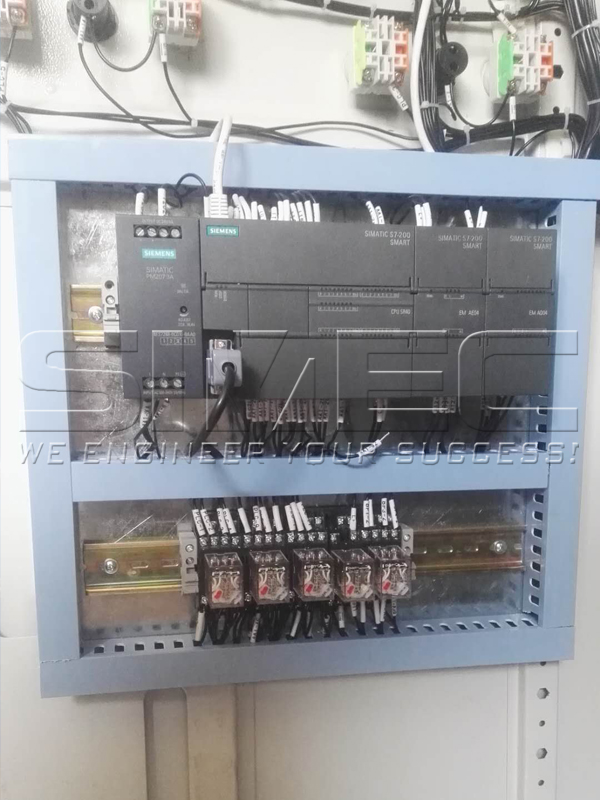

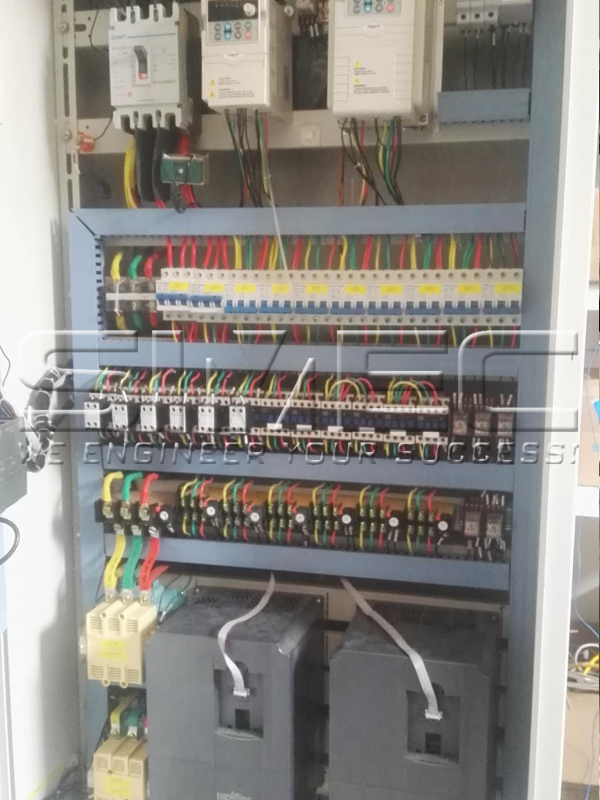

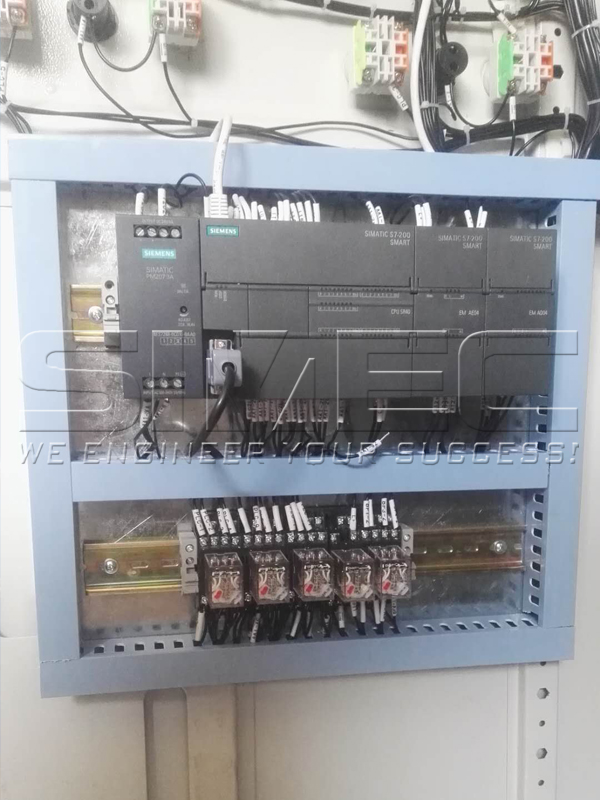

This set of rotary drum dryer mainly consists of five parts: rotary drum body, hot air stove, feeding & discharging system, convey system and PLC control system.

Based on the practical conditions and the client’s production requirement, this rotary drum dryer is equipped with automatic extinguishing system and instant moisture sensors.

The rotary drum dryer is not the first equipment that the client commissioned SIMEC to provide equipment for him, he had customized three sets of pellet mill ring dies from SIMEC before(http://www.mobilepelletplant.com/news/customized-ring-dies-delivery-to-poland.html).

| φ2900×11000 Triple Layer Drum Dryer Packing Details | |||||

| Art. No. | Equipment Name | Device Inside | Qty. | Size | Weight (t) |

| SIMEC① | Drum Body | None | 1 | 29 | |

| SIMEC② | Water Tank | Belt | 2 Rolls | 1600x1800x2000mm | 2.5 |

| Upper Supporting Roller | 28 | ||||

| Lower Supporting Roller | 5 | ||||

| Block Roller | 8 | ||||

| Motor | 6 | ||||

| B Type Triangular Belt 1850 | 4 | ||||

| Draught Fan Shock Pads 8pcs | 1 Bag | ||||

| Air Blower | 1 | ||||

| Air Blower Reducer | 1 | ||||

| Draught Fan Inlet Reducer | 1 | ||||

| Bolts + Silicon Steel Sheets 144 Blocks | 1 Case | ||||

| Belt Fastener + Soft Wire | 1 Box | ||||

| Belt Conveyor Sheath | 26 | ||||

| Draught Fan Outlet Transfer | 1 | ||||

| Straight Pipe 800mm | 1 | ||||

| Material Leveler | 1 | ||||

| Airlock | 1 | ||||

| Coupler | 1 | ||||

| Fire Grate Reducer + Coupler | 1 | ||||

| Belt Conveyor Upper Supporters 14 pcs | 1 Bale | ||||

| Belt Conveyor Lower Supporters 10 pcs | 1 | ||||

| Asbestos Cord (Adhesive Tape) | 1 Case | ||||

| Raincap | 1 | ||||

| Auxiliary Engine Pipe Flanges 8pcs | 1 Bale | ||||

| Fire Passage 600x500mm (Drum Fixing) | 1 | ||||

| SIMEC③ | Front Shell Cover | Single | 1 | 2500x2000x700mm | 0.35 |

| SIMEC④ | Rear Shell Cover | Single | 1 | 2500x2000x700mm | 0.36 |

| SIMEC⑤ | Hot Air Stove | Single | 1 | 6000x2500x2180mm | 15 |

| SIMEC⑥ | Hot Air Stove Feeder | Single | 1 | 6200x900x600mm | 0.4 |

| SIMEC⑦ | Stock Bin | Single | 1 | 1600x1600x1400mm | 0.3 |

| SIMEC⑧ | Cyclone Dust Collector | Single | 1 | 3100x1500x600mm | 1 |

| SIMEC⑨ | Fire Passage (Except Sparks) | Single | 1 | 1200x1200x1300mm | 1.2 |

| SIMEC⑩ | Feeder Screw Conveyor | Single | 1 | 3000x400x700mm | 0.8 |

| SIMEC⑪ | Ash Removal Machine | Single | 1 | 3200x1000x400mm | 1 |

| SIMEC⑫ | Dischager Screw Conveyor | Single | 1 | 6200x400x600mm | 1.8 |

| SIMEC⑬ | Supporting Roller Frame | Single | 1 | 2900x2200x700mm | 2.5 |

| SIMEC⑭ | Block Roller Frame | Single | 1 | 2900x2200x700mm | 2.8 |

| SIMEC⑮ | Draught Fan | Single | 1 | 3000x1700x1700mm | 2.5 |

| SIMEC⑯ | Shell Cover Legs | Single (Roll) | 4 | 2000x1000x400mm | 0.2 |

| SIMEC⑰ | Belt Conveyor Ribs | Single (Roll) | 26 | 1500x400x1000mm | 0.3 |

| 18 | 180°Elbow | Single | 1 | 1500x600x1000mm | 0.1 |

| 19/20/21 | 90°Elbow | Single | 3 | 1000x1000x500mm | 0.1 |

| 22 | Cyclone Dust Collector Stock Bin Legs | Single (Roll) | 12 | 200x200x1500mm | 0.3 |

| 23 | Ash Removal Machine Legs | Single | 1 | 1200x1000x400mm | 0.1 |

| 24 | Belt Conveyor Legs | Single (Roll) | 2 | 2000x800x500mm | 0.1 |

| 25/26/27 | Pipes | Single | 3 | 3100x1500x1500mm | 0.2 |

| 28 | Discharging Pipe | Single (Roll) | 2 | 1000x600x400mm | 0.1 |

| 29 | Spark Detect & Extinguishing Device | Single | 1 | 1000x1000x1000mm | 0.1 |

| 30 | Water Compress Device | Single | 1 | 1000x1000x1000mm | 0.1 |

| 31 | Water Pipes | Single | 1 | 400x400x200mm | 0.1 |

| 32 | Signal Cables | Single | 1 | 400x400x400mm | 0.1 |

| 33 | PLC Control Cabinet | 1000x500x2000mm | 0.3 | ||

| 34 | Fire Water Pipeline | 620x400x150mm | 0.01 | ||

| 35 | Signal Cable | 500x400x350mm | 0.03 | ||

| 36 | Water Booster | 1200x800x1350mm | 0.5 | ||

| 37 | Automatic Extinguishing System | 750x850x700mm | 0.1 | ||

All cargos could be delivered to Qingdao Port next week.

Drum before and in heat insulation layer process:

Unpainted and painted hot air stove:

Automatic extinguishing system:

Automatic extinguishing system controller panel and instant moisture sensors:

Cyclone and conveyor parts:

PLC control cabinet:

Screw feeder and painted drum body:

Cargos packged to be delivered:

Drum before and in heat insulation layer process:

Unpainted and painted hot air stove:

Automatic extinguishing system:

Automatic extinguishing system controller panel and instant moisture sensors:

PLC control cabinet:

Screw feeder and painted drum body:

Release date: 2018-05-03