Biomass Pyrolysis Research Unit Delivery to Wits University

Full degrees of pyrolysis experiments can be conducted by this apparatus, such as torrefaction, carbonization, gasification, etc. Reaction temperature, duration time and atmosphere can be adjusted according to research requirements.

To conduct whole-process research on biomass pyrolysis, and analyze solid/liquid/gaseous phase products under different reaction conditions, in late August 2022 Wits University began bidding to global enterprises and purchasing advanced lab pyrolyzer.

After half a year of comparison and investigation, Wits University finally selected SIMEC as the supplier of biomass pyrolysis technology and equipment among the six shortlisted suppliers to serve the research of biomass pyrolysis and carbon dioxide removal. The evaluation of SIMEC pyrolyzer by the university expert group is that SIMEC lab pyrolyzer is full featured, the temperature control is more accurate, the reactor design principle maintains consistency to the operation requirements of large-scale projects, so the experimental data can better serve commercial projects.

In late 2023, the official representative of Wits University, Professor Yasser visited SIMEC to conduct pre shipment acceptance of pyrolysis research laboratory apparatus. We did pyrolysis tests using algae and wood sawdust as feedstock separately. Professor Yasser was very satisfied with the performance of lab analyzer system.

Syngas online monitoring and analysis module enables the researcher to gain complete data of synthetic gases, such as composition, proportion, thermal value, etc., and to graph dynamic data curves. Detectable gas range: CO, CO2, CH4, H2 , O2 , CnHm. The detectable gas range can be customized according to client’s requirements.

Gas Analyzer

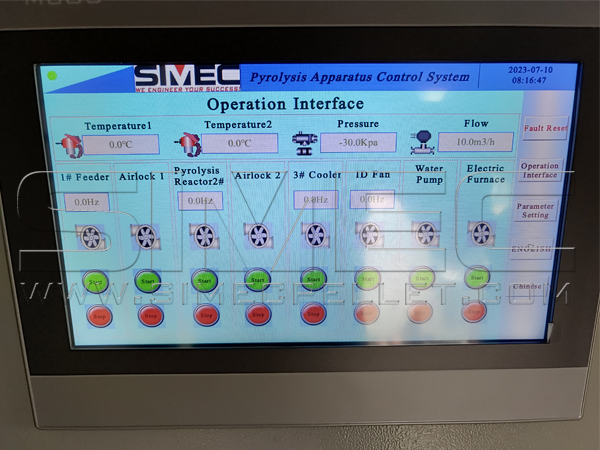

Control Interfac

Packing Details: 1 container said to contain 1 package

| Mark |

Packing Dimensions (L*W*H) |

Volume (m³) |

Gross Weight (kgs) |

Packing Details |

|

SIMEC 01 |

4300*1800*2200 mm | 17.03 | 2390 |

Lab pyrolyzer, gas Analyzer. HS code: 84198 99090 |