Rice Husk Charring Experiment

Pyrolyzed Rice Husk

Rice Husk Char

Owing to the characteristics of rice husk charcoal, it mainly has three industrial usages:

1. Thermal Insulation Material

The rice husk charcoal is clean without any impurities. It has light specific gravity and low thermal conductivity which comes out excellent thermal insulation capability. In metallurgy and casting, processed rice husk charcoal is widely adopted to insulate the molten steel or molten iron, which can decrease the heat loss caused by radiation, convection and conduction and reduce the discharging temperature and energy consumption under the premise of the casting temperature of the metal. It can also lessen shrinkage cavity of steel, which is very beneficial to improve the yield of steel.

2. Raw Material of Activated Carbon

The basic ingredients of rice husks charcoal are carbon and silicon. No harmful metallic chemical elements such as arsenic and lead are contained.

Moreover, after the high temperature charring process, the pesticide pollution remains on the rice husk is eliminated. And the cells of rice husk form a loose structure with multiple micropores, which makes rice husk charcoal a good source of raw material for activated carbon production.

The activated carbon made of rice husk charcoal is non-toxic and harmless, and can be used for decolorization and purification of medicine, sugar and food industry.

3. Agriculture and Environment Protection

In agriculture, the pyrolyzed rice husk can be utilized to improve crop yield by keeping the temperature, loosing and balancing the ph of the soil. It’s also a medium to cultivate high quality seedlings. In the environment, charred rice husk can be used for air purification, domestic water purification and sewage treatment.

Charring test is carried out by Biomass Laboratory Pyrolysis Apparatus . The compact design of the equipment enables the operator to conduct biomass pyrolysis experiments in a limited space. The simple and accurate operation of this equipment help the clients, who will set up commercial biomass pyrolysis projects, to collect the relevant experimental data for further analysis and research, then improve commercial operation.

Biomass Pyrolysis Apparatus

Rear View of Pyrolysis Apparatus

Features:

- The equipment is adopted with PID intelligent temperature controlling & monitoring system, which makes sure the highly precise and stable reacting temperature;

- The specialized control cabinet enables simple operation & adjustment;

- Accessible Gas Sampling: It is convenient to collect the syngas through the special designed syngas sampler at Sampling Interfaces.

- Including syngas burners, and flame temperature detector.

- Modular design contributes to minimizing clients’ installation and commissioning work. Before delivery, all of the mechanical and electrical components will be mounted on specially designed operation platform, and commissioned in SIMEC fabrication mill. The completely mounted apparatus can be loaded into a standard 20’ shipping container.

- Optional Syngas Online Monitoring and Analysis Module enables the researcher to gain complete data of synthetic gas, such as composition, proportion, thermal value, etc., and to graph dynamic data curves. Detectable gas range: CO, CH4, H2, CO2, N2, C2H6, C3H8, CnHm, etc. The detectable gas range can be customized according to client’s requirements.

EXPERIMENTE DATA:

Date: Oct. 20, 2020

Raw Material: Rice Husk

Rice Husk

Rice Husk Moisture

Moisture: 4.3%

Status: Unpulverized

Size: 4mm

Due to the uniform size and good liquidity of rice husk, it can be fed to the pyrolysis apparatus smoothly without any pulverizing treatment.

When starting the experiment, firstly feed the rice husk into the feeding hopper and cover the top cap to isolate the air, then heat the the reaction chamber. Temperature of pyrolysis is set at 600℃. It takes 46 minutes for the temperature to rise from 19℃(room temperature) to 600℃. At this time, open the sluice valve to feed the rice husk into pyrolysis reaction chamber.

The feeder adopts variable frequency speed design. A stable material feeding flow which is required by charring process can be achieved by setting the feeding speed of feeder at 23.6Hz.

The pyrolysis reactor can also adjust the process time according to the variety of materials. Regarding the rice husk, the reaction time can be set at 18Hz to realize continuous and stable reaction.

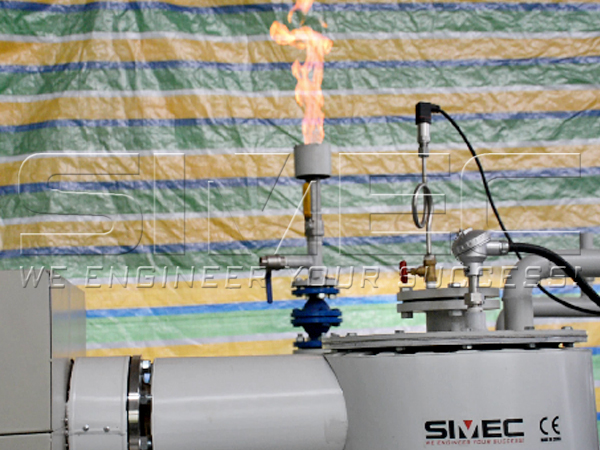

After being purified by a complete set of purification devices, the combustible syngas is ignited at the No. 2 burner.

Combustible Syngas Temperature

PurifiED syngas Combustion

The temperature of the combustion flame reaches 552.6℃. No harmful gas emissions to the air during the whole experiment.

Status: Rice Husk Charcoal

Process Temperature: 600℃

Output Char Temperature: 50℃

Weight Before Pyrolysis: 2kg

Weigh After Pyrolysis: 0.8kg

CONCLUSION:

A continuous and stable pyrolysis charring reaction of rice husk can be achieved at 600℃ processing temperature. Uniform size and moisture of rice husk is helpful to keep continuous and stable charring process. The charcoal output ratio of rice husk at 600℃ can reach up to 40% (Before: 2kg, After: 0.8kg). The process can produce sufficient amount of combustible syngas. After purification, the gas can be used as fuel for power generation, heating and other purpose.

In conclusion, rice husk is a high quality biomass fuel for char production. Its large-scale co-generation of char and gas will have good economic and environmental benefits.

© Copyright of articles and pictures on this site belongs to SIMEC. Any company, media, website or individual are not allowed to reprint, reproduce, repost, modify or use in other ways without permission. Otherwise SIMEC will have the right to pursue legal responsibilities.