Research on Palm Oil Mill and EFB Utilization

As one of the traditional backbone industries in Malaysia, the palm oil mills and the national palm oil research institute are always seeking the way to optimize the production, and improve the added value of the by-products. SIMEC focus on the research of palm EFB utilization. Below is the typical process flow of palm oil mills. Palm EFB is generated from the second step.

Palm Oil Mill

Palm Oil Plant

STERILIZATION

FFB (Full Fruit Bunch), unloaded at the oil mills would be sterilized in the sterilizing tanks firstly. The FFB turns to be soft after being boiled and steamed under the high temperature and pressure condition in the tanks.

Loaded FFB to be Sterilized

FFB Sterilizing Tanks

THRESHING

The soft FFB is threshed by the threshing machine. During this process, the palm fruits are separated from the EFB. After sifting, the fruits are conveyed to the next process, and EFB would be conveyed to the EFB landfill.

Threshing Machine

Palm Fruits are Pressed

DIGESTING

The fruits would be pre-pressed and mixed in a crushing tank. The crushed fruits are easy to be pressed in the next process.

PRESSING

Now the crushed palm fruits are pressed by the double screw oil mills. The crude palm oil (CPO) is pressed out. The mesocarp fiber and palm nuts are screened out from the CPO and conveyed to the following step. The screened CPO will be clarified statically, meanwhile the sludge is separated from the CPO. Finally, the CPO would be stored in the oil tank after purifying and drying.

Palm Oil Presser

Palm Oil Extruder

DE-PERICARPING

In this stage, the nuts are separated from the mesocarp fiber by gravity in the cyclone. The separated fiber is used as the fuel for the boilers, which supply the steam to the sterilization and the steam turbine.

Mesocarp Fiber

Palm Nuts

NUT CRACKING

The separated nuts are cracked by the cracker, the palm kernel shell (PKS) and kernel are separated by gravity in the cyclone.

Palm Kernel

Palm Kernel Shell

DRY SEPARATION

The separated dry PKS from the cyclone is used as the fuel for the boilers.

WET SEPARATION

Now the kernel would be almost completely separated from the PKS again through the washing separation system. The wet PKS would be dried, to be sold or used as the fuel for the boilers; the kernel would be also dried and stored. Most of the palm oil mills would sell the kernel to the kernel oil mill.

Actually, several kinds of by products would be produced during the palm oil milling. At last only 23% palm oil can be stored in the tank for sale. The mesocarp fiber and the PKS can be used as fuel for their own boilers. The PKS can certainly be sold to its buyers at a good price. Among all of the residues from the P.O.M., most of them are EFB. Here is a MATERIAL BALANCE OF P.O.M. for reference.

Palm Oil Mill

Palm Oil Plant

STERILIZATION

FFB (Full Fruit Bunch), unloaded at the oil mills would be sterilized in the sterilizing tanks firstly. The FFB turns to be soft after being boiled and steamed under the high temperature and pressure condition in the tanks.

Loaded FFB to be Sterilized

FFB Sterilizing Tanks

THRESHING

The soft FFB is threshed by the threshing machine. During this process, the palm fruits are separated from the EFB. After sifting, the fruits are conveyed to the next process, and EFB would be conveyed to the EFB landfill.

Threshing Machine

Palm Fruits are Pressed

DIGESTING

The fruits would be pre-pressed and mixed in a crushing tank. The crushed fruits are easy to be pressed in the next process.

PRESSING

Now the crushed palm fruits are pressed by the double screw oil mills. The crude palm oil (CPO) is pressed out. The mesocarp fiber and palm nuts are screened out from the CPO and conveyed to the following step. The screened CPO will be clarified statically, meanwhile the sludge is separated from the CPO. Finally, the CPO would be stored in the oil tank after purifying and drying.

Palm Oil Presser

Palm Oil Extruder

DE-PERICARPING

In this stage, the nuts are separated from the mesocarp fiber by gravity in the cyclone. The separated fiber is used as the fuel for the boilers, which supply the steam to the sterilization and the steam turbine.

Mesocarp Fiber

Palm Nuts

NUT CRACKING

The separated nuts are cracked by the cracker, the palm kernel shell (PKS) and kernel are separated by gravity in the cyclone.

Palm Kernel

Palm Kernel Shell

DRY SEPARATION

The separated dry PKS from the cyclone is used as the fuel for the boilers.

WET SEPARATION

Now the kernel would be almost completely separated from the PKS again through the washing separation system. The wet PKS would be dried, to be sold or used as the fuel for the boilers; the kernel would be also dried and stored. Most of the palm oil mills would sell the kernel to the kernel oil mill.

Actually, several kinds of by products would be produced during the palm oil milling. At last only 23% palm oil can be stored in the tank for sale. The mesocarp fiber and the PKS can be used as fuel for their own boilers. The PKS can certainly be sold to its buyers at a good price. Among all of the residues from the P.O.M., most of them are EFB. Here is a MATERIAL BALANCE OF P.O.M. for reference.

| ITEMS | % TO FFB |

| Empty Fruit Bunch (EFB) | 20-23 |

| Bunch Ash | 0.5 |

| Sterilizer Condensate | 16 |

| Sterilized Fruitlet | 67 |

| Crude Oil | 65-75 |

| Sludge | 40-45 |

| Decanter Solid | 3 |

| Oil | 23 |

| Mesocarp Fiber | 13-15 |

| Nut | 10-14 |

| Shell | 6-7 |

| Kernel | 5-6 |

| Effluent | 80 |

Some of EFB are used to be processed into long fiber, exported abroad and processed into palm mattress. However, to export the long fiber is not a good business any more, because of the reduced demand of the target market. Sometimes the EFB is also processed into fertilizer for plantation or made into mulch for gardening. But most of the EFB is just stored in the open land beside the mill. Over time, more and more EFB is accumulated. How to utilize the EFB effectively or convert the residue into valuable products is a real problem to the POM owners.

Pressed EFB Stored at Open Land

Palm EFB Pellets

Palm EFB Pellet Mills

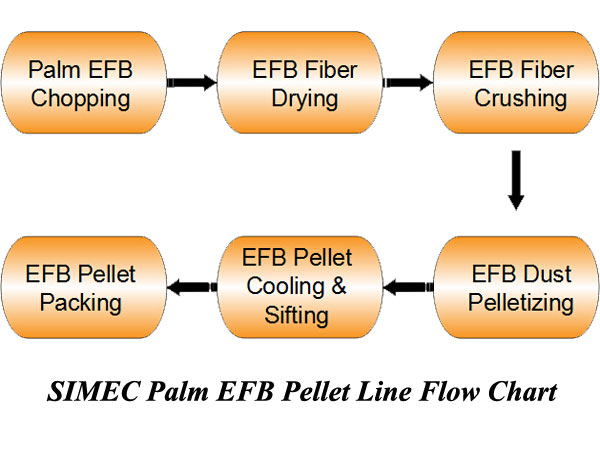

SIMEC has been in the R&D to improve the value of palm EFB for years. One of our most reliable solutions is to make palm EFB pellets. Besides providing technology & equipment to the investors who want to convert palm EFB into palm EFB pellets, SIMEC can also introduce the market of EFB pellets to the investors.

Since recent two years, China and Japan have been building up many biomass power plants, which use biomass pellets as the fuel. The demand amount of biomass pellets from these two countries is increasing rapidly. One medium-sized biomass power plant would consume 20000-25000 tons of biomass pellets per month. The total amount of the two countries’ demand on biomass pellets will be very huge.

SIMEC has already made good quality EFB pellets successfully in plant at Malaysia since the year of 2008. We are devoted to improving the EFB pellet processing technology with less power consumption and less investment cost. We provide our clients with the most appropriate proposal and reliable equipment; meanwhile the professional SIMEC technician team will help our clients complete the project installation, and also provide commissioning and training services. In addition, we are able to supply the project consultancy services and marketing services.