R&D for Eucalyptus Wood Pellet Production

Eucalyptus are well adapted to dry, infertile sites such as degraded land no longer suitable for agriculture. They can also contribute to the protection of biodiversity, water and soil systems:

BIODIVERSITY

Around the world, pressure is being placed on natural forests due to demand for fuel wood and timber. Eucalypts are a fast-growing alternative to native species, which are often difficult to establish. Eucalypts can save biodiversity by preventing the destruction of natural forests.

WATER

Careful management of hydrological impacts is important for any landuse. Forested catchments reduce water yield compared to non-forested catchments. However, forests regulate water flow, preventing extremes. The effect of eucalypts in reducing water yield is probably less than that of pine and greater than that of other broad leaved species. One important aspect of eucalypts is water use efficiency, which is much greater than other tree species, meaning that per unit of water consumed, eucalypts produce more biomass than alternative plantation species. Eucalypt plantations can improve the infiltration capacity of the soil to reduce run-off and to activate the soil water charging, filtering and cycling process. Practices to improve interception and infiltration include retention of litter, development of an understory or of a compatible native ground cover; development of a nitrogen fixing compatible ground cover, and in water short areas lower tree stocking to reduce water consumption.

SOIL

Eucalypts specifically do not cause soil erosion and if managed correctly can sustain or improve the condition of the soil on a site. Eucalypts are well suited to degraded soils and will often grow where native species will not grow. For this reason, eucalypts can be used to restore damaged forest ecosystems where natural regeneration is not possible in the short term. Eucalypt foliage and bark contains a large amount of nutrients, so when plantations are harvested it is a good management practice to retain these on site to maintain the nutrient status of the soil. Application of fertilizer can be used to add nutrients to the soil. Allelopathy of eucalypts has not been shown, which is supported by the ability to grow many crops in intercropping agroforestry systems. The use of soil conservation techniques combined with nutritional management results in eucalypt plantation being able to be sustained on the same site for many rotations without degradation of the soil.

As agreed, 20 kgs of eucalyptus wood waste sample in three packages were delivered from Lao PDR and arrived at SIMEC R&D center in May 2023.

Description of Sample _ As received:

Moisture: Below 10%.

Size: Maximum 65*50*3mm.

Based on the above parameters, it’s preliminarily judged that the sample of eucalyptus wood chips needs further size reduction process before pelletizing.

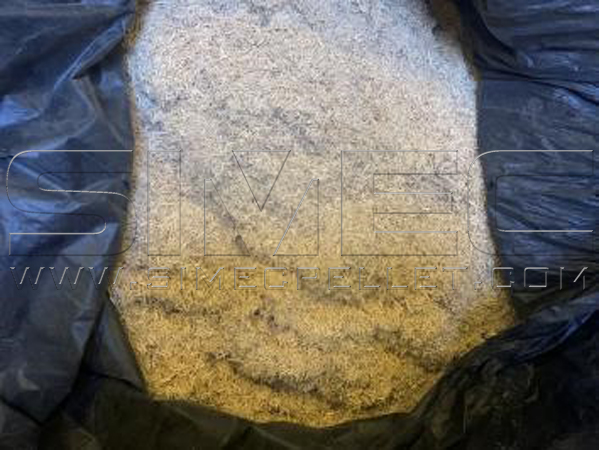

Description of Sample _ After size reduction:

Status: Ground wood particles

Moisture: Below 10% (6.9%~7.6%)

Size: Smaller than 10mm.

Based on the above parameters and our experience, the moisture needs to be adjusted before pelletizing.

Due to eucalyptus wood is a kind of tropical hard woods, there are some Needle-like wood chips which need to be further grinded. Otherwise, it may reduce the efficiency of pelletization process. Thus, we adopted fine pulverizing process to avoid its impact on the next pelletizing process.

Status: Fine pulverized wood chips

Moisture: below 10%

Size: Smaller than 5mm. Diameter of the needle-like wood chips 2-3mm, still very hard.

The result presents there is some certain ratio of big size needle-like wood chips after fine pulverizing.

In an initial pelleting test, the wood chips mixed with the fine powder and adhere to the grooves of roller shell. As a result, the press rollers of pellet mill slipped, thus there was no longer any pressure generated to drive the material that remains in the ring die hole out. In the light of this, SIMEC R&D team worked out a solution to ripen and soften the pulverized eucalyptus wood chips. It significantly helps to activate the action of lignin and decreases resistance while pressing. The wood chips became much easier to pass through the holes of ring die. The eucalyptus wood chips combine to pellet form under the effect of pressure and lignin which is the natural binder.

| Description of Goods: Solid Biomass Fuel (Eucalyptus Wood Pellet, Diameter: 8mm) | ||

| Parameter | Test Method | Value |

| Total moisture (Wet basis) | CEN/TS 14774 | 5.77% |

| Ash (Dry basis) | CEN/TS 14775-2004 | 1.38% |

| Volatile matter (Dry basis) | CEN/TS 15148-2005 | 81.17% |

| Fixed carbon (Dry basis) | ISO 17246:2005 | 17.52% |

| Sulphur (Dry basis) | CEN/TS 15408 | 0.041% |

| Gross calorific value (Dry basis) | CEN/TS 14918 | 4642 Kcal/kg |

| Density (Dry basis) | CEN/TS 15103-2005 | 684 kg/m3 |

| Total carbon (Dry basis) | GB/T 476-2008 | 44.53% |

Based on the testing findings and samples, SIMEC client is full of confidence for the commercial eucalyptus wood pellet project, and can lock in potential pellet purchasers and extend the market in advance. We also outlined the essential processes and experiences to help guide commercial projects.

© Copyright of articles and pictures on this site belongs to SIMEC. Any company, media, website or individual are not allowed to reprint, reproduce, repost, modify or use in other ways without permission. Otherwise SIMEC will have the right to pursue legal responsibilities.