Palm EFB Water Washing System

Ash content of palm EFB has negative effect on combustion performance which is mainly caused by potassium (K). Unwashed palm EFB may contain up to 7 % of ash of which potassium can be up to half of it. Water washing is an effective method to reduce potassium content in palm EFB. Up to 90% of potassium can be washed out since it is soluble in water.

SIMEC has developed a cost effective palm EFB washing system that can be integrated in palm EFB pellet plant. The washing facility will be placed after the size reduction pretreatment and before the drying of the feedstock. The washing process is continuous and automatic.

Design Parameters of Palm EFB Water Washing System:

Process capacity 14.3 t/h moisture content about 65%(wet basis), 5 t/h palm EFB (dry basis) will be made;

Feeding fiber length is 0.5 – 1 inch (or 1.25 – 2.5 cm);

Water to biomass ratio 10:1;

Average residence time 12 minutes;

Tap water without additives is used;

No heating of the water;

Amount of potassium washed out 90%.

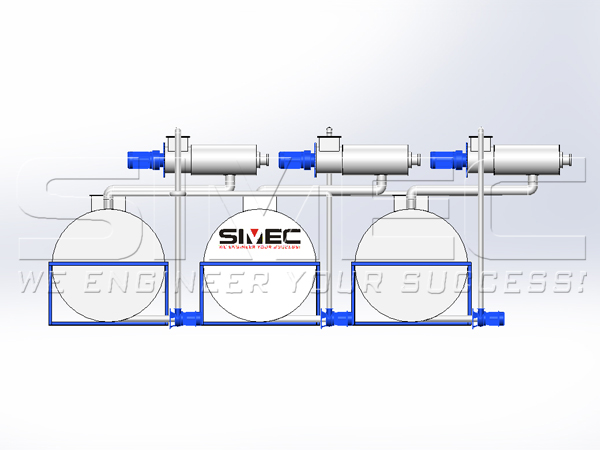

After practices of single tank washing setup and multiple tank setup, based on the aim of minimize water usage, water waste and energy usage while maximizing the washout of potassium, SIMEC comes to the conclusion that three water washing tanks setup is the wiser choice to maximize benefits.

Unwashed Palm EFB

Washed Palm EFB Fiber

In the water tanks the actual washing of the palm EFB takes place. The tanks will be sized at 10 liters of water for each kilogram of palm EFB is inside it. An average residence time of 12 minutes per tank will be maintained to ensure that 1 ton of palm EFB is in each tank at any given time. In order to wash 5 tons of palm EFB per hour, the size of tanks should be 10m3.

Working Flow of Three Tanks Palm EFB Water Washing Apparatus

Crushed palm EFB fiber are conveyed into the tank, a mixer is used in order to create a turbulent flow inside the tank to improve diffusion of ashes coming out of the biomass and have a uniform distribution of the palm EFB fiber.

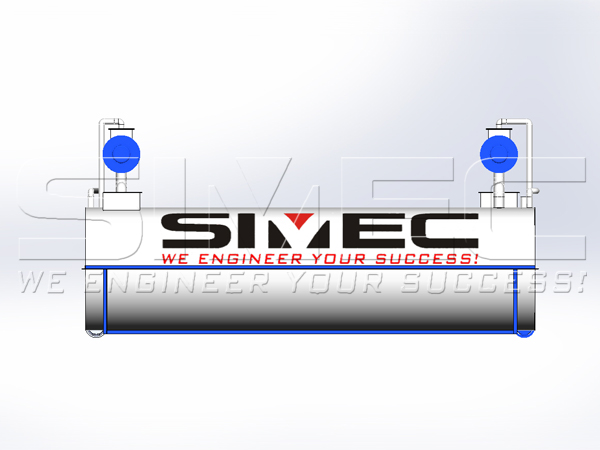

After 12 minutes, the mixture of water and palm EFB fiber will be pumped to the inlet of a screw press that is positioned above the pump. The screw press is used for dewatering and pressing the biomass after washing. 50% of the mositure content of water-EFB mixture will be dewatered.

After dewatering, the palm EFB fiber will be conveyed to the second and third tank and repeat the above steps.

Palm EFB Water Washing Plant

Palm EFB Water Washing System

In order to save the cost of water, SIMEC designed the three water tanks setup to add clean water only to the last tank. When Unwashed palm EFB is entered at the first tank and pumped to the next, the clean water will be pumped in the opposite way to the previous tank.

It is estimated that in the first tank 50% of the potassium is removed, the second one 30% and the third one 10% and thus a total removal of 90% of the potassium is realized.

Being treated by SIMEC water washing technology, palm EFB pellets can meet the requirements of Japan biomass power markets and be approved by Japan FIT scheme.

SIMEC focus on commercial projects that upgrade the value of palm EFB by advanced technology.

For more information, please contact info@simecpellet.comIt is estimated that in the first tank 50% of the potassium is removed, the second one 30% and the third one 10% and thus a total removal of 90% of the potassium is realized.

Being treated by SIMEC water washing technology, palm EFB pellets can meet the requirements of Japan biomass power markets and be approved by Japan FIT scheme.

SIMEC focus on commercial projects that upgrade the value of palm EFB by advanced technology.