Palm EFB Pellet Fuel Powers Japan

In recent years, Japan takes unprecedented steps to build many new biomass power plants fueled by wood pellets and other biomass fuels. Japan’s demand for wood pellets has grown many times over the past 5 to 6 years, catering to its steadily increasing consumption of pellet fuel for biomass power plants and coal-firing power plants.

| Calendar Year | 2017 | 2018 | 2019 | 2020 | 2021 | 2022 |

| Beginning Stocks (kilotons) | 19 | 26 | 50 | 75 | 95 | 17 |

| Imports (kilotons) | 506 | 1,060 | 1,614 | 2,028 | 3,117 | 4,800 (est.) |

| Consumption (kilotons) | 626 | 1,167 | 1,736 | 2,156 | 3,134 |

When Japan tries to expand its biomass power plants and wood pellets import amount, it also has been searching for other alternative and sustainable biomass fuels, ensuring its constant energy safety.

Over recent years, some fleet-footed Japanese corporations have invested some pilot plants for producing palm EFB pellets in South East Asia. As one of the main byproducts from CPO mills, its sustainable access makes palm EFB pellets become the new favorite in Japan’s biomass pellet market.

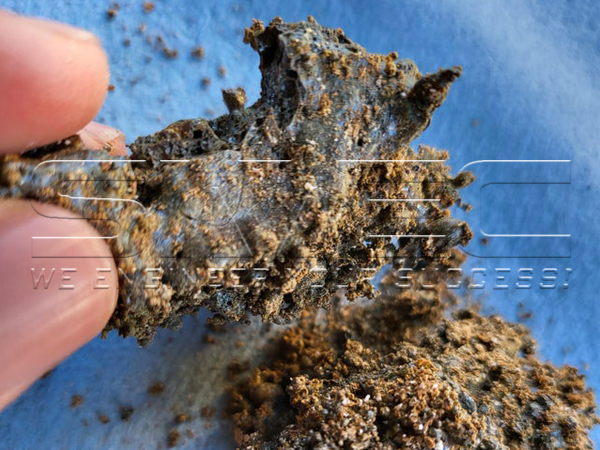

Consequently, the corrosion and slagging problem caused by the combustion of palm EFB pellets will obviously increase the boiler OPEX and decline its life span.

Case 1. A Palm EFB Power Plant in Thailand

One of SIMEC clients in the south part of Thailand has run a palm EFB power plant for decade. But they have suffered from the slagging problem in biomass boilers for years. Because palm EFB is just pressed and cut, then conveyed to the combustion chamber. Although it is a specialized biomass boiler, slagging always occurs and is inevitable. So they have to stop operation frequently to inspect and clean the slag. The shut-down significantly affects the economic benefit of power plant. Actually, they have two boilers, one has been abandoned years ago due to the corrosion.

SIMEC was involved in the setup of palm EFB pellet projects in Malaysia. The SAPB1500 pellet burner and hot gas generating system provides heat source to palm EFB drying process. The fuel is untreated palm EFB pellets. After a few days of operation, slagging and the resulting clogging will happen inside the combustion chamber of pellet burner. The client has to stop pellet burner frequently to clear the slag.

As supplier of processing technology and equipment, SIMEC has been working on a number of clean palm EFB pellet projects in South East Asia. The “clean” palm EFB pellets have been certified and exported to Japan. It is foreseen that more and larger commercialized palm EFB pellet projects will be landed in South East Asia, catering to the intense demand of biomass pellet fuel in Japan, even in South Korea in the near future.

© Copyright of articles and pictures on this site belongs to SIMEC. Any company, media, website or individual are not allowed to reprint, reproduce, repost, modify or use in other ways without permission. Otherwise SIMEC will have the right to pursue legal responsibilities.