Biochar Research Advancing Net Zero

Biochar has garnered significant attention due to its promising carbon sequestration capability, as demonstrated through various studies. Universities, scientific institutions, and companies focused on carbon removal research and project development are striving to optimize biochar production and accommodate a diverse range of feedstock. To accomplish this, these organizations require a versatile lab-scale biomass pyrolysis apparatus for biochar & CCS research.

SIMEC biomass pyrolysis laboratory apparatus stands as a comprehensive research platform for biochar & CCS technology. With a wide range of pyrolysis temperature reaching up to 1100°C and flexible reaction time, it supports the research of torrefaction, carbonization, gasification and other slow or fast pyrolysis process under different reaction temperature and material flow rate.

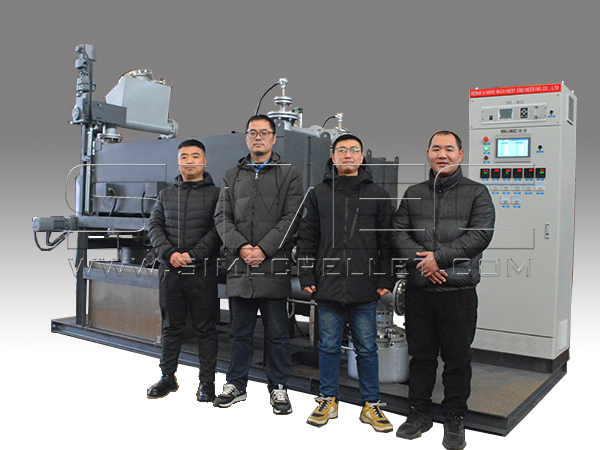

In January 2025, SIMEC delivered a biochar research unit to the project developers in Brazil.

Using state-of-the-art technology, the research unit integrates more valuable features to improve the efficiency and quality of biochar research, and the study of carbon capture and sequestration technology.

The Brazilian researchers will start by producing biochar using various types of woody biomass, agro residuals and biomass pellets, achieving the European Biochar Certificate (EBC) standards.

SIMEC biomass pyrolysis laboratory apparatus stands as a comprehensive research platform for biochar & CCS technology. With a wide range of pyrolysis temperature reaching up to 1100°C and flexible reaction time, it supports the research of torrefaction, carbonization, gasification and other slow or fast pyrolysis process under different reaction temperature and material flow rate.

In January 2025, SIMEC delivered a biochar research unit to the project developers in Brazil.

Using state-of-the-art technology, the research unit integrates more valuable features to improve the efficiency and quality of biochar research, and the study of carbon capture and sequestration technology.

The Brazilian researchers will start by producing biochar using various types of woody biomass, agro residuals and biomass pellets, achieving the European Biochar Certificate (EBC) standards.

In addition to the standard configuration for producing consistent EBC-standard biochar, this biomass pyrolysis research apparatus is also equipped with the following modules:

1. Syngas online monitoring and analysis module: providing real-time monitoring and analysis of the composition and calorific value of syngas, and automatically producing real-time curves and historical curves.

2. Syngas reforming module: unlocking the research potential of cutting-edge technologies, such as syngas composition engineering, upgrading processes, tar cracking, purification, and more, empowering the researchers to explore the full spectrum of possibilities.

3. Thermal air oxidation module: high-precision trace gas addition control system.

4. Comprehensive data logging module: operation record, running data, temperature, pressure, gas flow, gas composition, and all the other data can be logged automatically, and can be exported as well.

5. Far distance monitoring & control module: SIMEC engineers can provide remote training, guidance, and upgrades to customers around the world from R&D office. The access protocol for each device is unique and confidential.

2. Syngas reforming module: unlocking the research potential of cutting-edge technologies, such as syngas composition engineering, upgrading processes, tar cracking, purification, and more, empowering the researchers to explore the full spectrum of possibilities.

3. Thermal air oxidation module: high-precision trace gas addition control system.

4. Comprehensive data logging module: operation record, running data, temperature, pressure, gas flow, gas composition, and all the other data can be logged automatically, and can be exported as well.

5. Far distance monitoring & control module: SIMEC engineers can provide remote training, guidance, and upgrades to customers around the world from R&D office. The access protocol for each device is unique and confidential.

Furthermore, SIMEC has also developed a research equipment management system, which allows the creation of experimental project archives and operator accounts. The biochar equipment can only be controlled with the authorization of the administrator. There is no limit to the number of operator accounts. All the operations will be recorded and filed.

Considering the client's urgent need for the apparatus, SIMEC expedited production, resulting in a two-month advancement in delivery. The entire device was skid-mounted for ease of movement and layout. SIMEC team completed the commissioning work in workshop prior to delivery. The complete set could be loaded into a standard 20 foot marine container.

Packing details:

| Mark | Equipment Name |

Packing Dimensions (L*W*H) |

Volume | Gross Weight |

| SIMEC 01 | Biochar research apparatus | 4400x2150x2250 mm | 21.29 m³ | 2030 kgs |

© Copyright of articles and pictures on this site belongs to SIMEC. Any company, media, website or individual are not allowed to reprint, reproduce, repost, modify or use in other ways without permission. Otherwise SIMEC will have the right to pursue legal responsibilities.