Palm EFB Biochar Experiment and Analysis

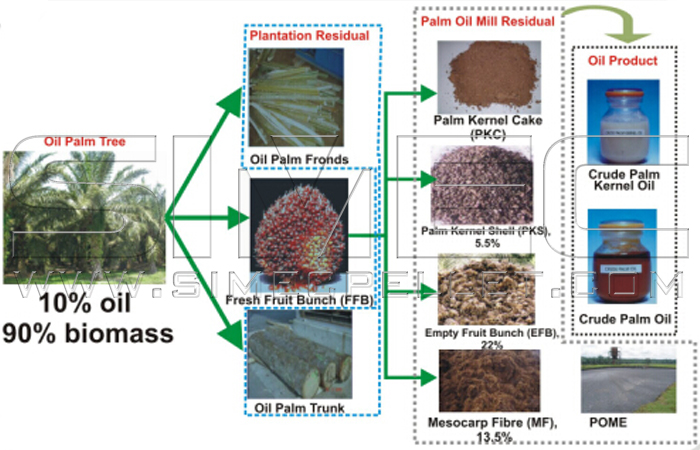

The mesocarp fiber and PKS (palm kernel shells) are used as fuel for boilers in CPO (crude palm oil) mills, and are also sold as fuel in the market. In contrast, only a small quantity of palm empty fruit bunches are used for mulching and fertilizer composition, rather than being combusted in industrial boilers. This is due to the high moisture content and alkali metal composition of the EFB. As a result, large piles of unused palm EFB often accumulate at palm oil mills, posing challenging problems of environmental pollution and threats to local ecological balance.

SIMEC was entrusted to conduct a trial production of palm EFB biochar, using 20 kgs of palm EFB delivered from Indonesia. The biochar production process was carried out in an oxygen-depleted environment at a specific temperature and for an appropriate duration.

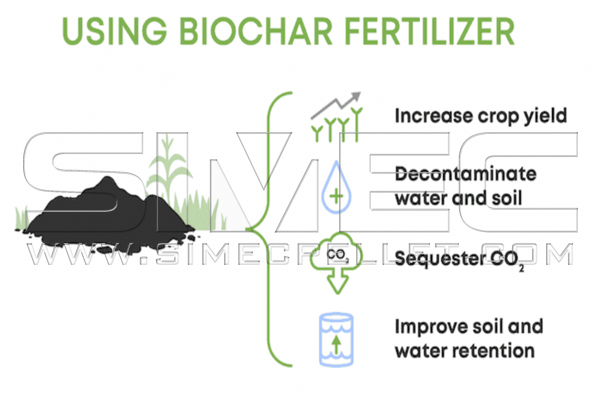

Then, palm EFB biochar was sent to an accredited third-party laboratory for comprehensive analysis. The analytics indicate that palm EFB biochar meets the standard of EBC-Feed class I and EBC-AgroBio class II. Very low PAHs content and low molar H/Corg ratio. This means palm EFB biochar can offer long-term carbon storage in soil. Making palm EFB biochar is an efficient waste management solution, meanwhile it also promotes atmospheric carbon removal. The positive characteristics of palm EFB biochar have been verified by experiments and analysis.

1.Gain insight into product quality under different production conditions.

2.Determine the optimum processing technology for future commercialized projects.

3.Understand the mass loss dynamics for future commercialized production.

4.Provide practical data to support the feasibility study of commercialized projects.

© Copyright of articles and pictures on this site belongs to SIMEC. Any company, media, website or individual are not allowed to reprint, reproduce, repost, modify or use in other ways without permission. Otherwise SIMEC will have the right to pursue legal responsibilities.