Fully Automatic Wood Pellet Packing Machine

I. Introduction of LB350 Fully Automatic Bag Given Packaging Machine LB350 fully automatic bag given packaging machine is the latest model of our company, it can achieve the steps of feeding bags, opening bags, clamping bags, filling the bags, output transport and fully automatic sealing, the whole process is unmanned operation. The machine unit is controlled by 10 inch colorful touchable screen made by Taiwan Weilun, it is more ergonomic, easier to operate, convenient to switch the bag specifications and maintain the machine, the PLC controller parts adopt the international brands, the performance is reliable, the running of machine is stable and safe.

Fully Automatic Wood Pellet Packaging Machine

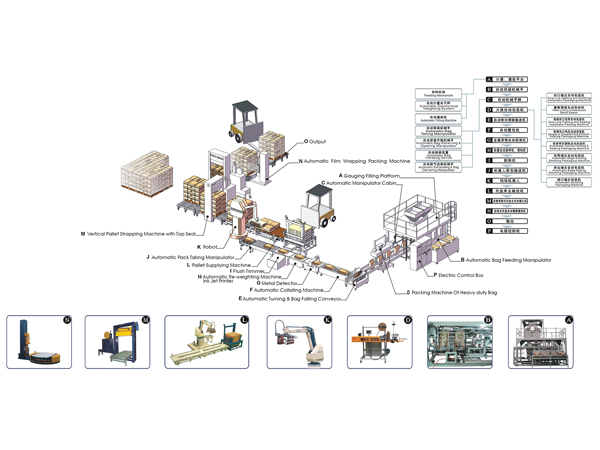

Automatic Bagging Flow Chart

Technique Features

- Compact structure, small size, good visibility.

- Control unit adopts the programmable logic controllers.

- Touchable graphic display.

- Built-in adjustable parameters.

- Product quantity can be directly displayed.

- Record the yield of each day, easy to be checked.

- Configured with operational analysis chart.

- Normal fault auto diagnosis and stop, displays the fault position on the screen.

- Heat part adopts the programmable logic controllers (PLC), the display and setting of temperature are showed on the touchable screen, direct and easy to be adjusted.

- Easier to switch the bag specifications.

II. Palletizing robot

The shell body of palletizing robot series is made of aluminum and FRP, the structure is light with low noise. It has the most sensible ability to use the power to reduce the power consumption.

The robot adopts the standard parts produced by brand manufacturers, the part is small in number and high reliability, greatly reduce the failure rate of the machine and also reduces the number of customers spare parts inventory.

From low speed to high speed, from packing bag to carton, from palletizing one kind of production to palletizing varies kinds of production, customers can find the robot they need from the palletizing robot series.

Palleting Robot

Adopts the easy operation touchable screen

The shell body of palletizing robot series is made of aluminum and FRP, the structure is light with low noise. It has the most sensible ability to use the power to reduce the power consumption.

The robot adopts the standard parts produced by brand manufacturers, the part is small in number and high reliability, greatly reduce the failure rate of the machine and also reduces the number of customers spare parts inventory.

From low speed to high speed, from packing bag to carton, from palletizing one kind of production to palletizing varies kinds of production, customers can find the robot they need from the palletizing robot series.

Palleting Robot

- Easy to operate and the information is clearly displayed on the screen.

- All actions and functions can be made sure through the touchable screen.

- Switch the data block number can shift the produce mode to complete different production tasks.

- Easy to chose the style of palletizing. All of the palletizing styles are displayed on the screen, customers can chose it from the screen.

- There are three styles of palletizing, customers can chose, read and correct the parameters by clicking the screen.

- Of all models of machine, customers can freely chose the colorful screen.

III. Automatic Pallet Store System

Put the pallets to the “pallet place” 10 blocks for a time, the system will automatically send a pallet to the “palletizing position”, and the robot grips the box to the pallet (customers can set the style, number and floors of placing boxes)the palletized boxes are transported to the end, get into “Product output section”, and the operator put the palletized product into the storehouse by forklift.

IV. Device List

More parameters and operate methods can be found in the Service Manual, please download the PDF manual of LB350 Fully Automatic Wood Pellet Packaging Machine for detail information.

IV. Device List

| No. | Name (Type) | Unit | Amount |

| 1 | Pellet Weighing Machine | - | 2 |

| 2 | Rack Platform | Set | 1 |

| 3 | LB350 (PE Bag) Fully Automatic Packaging Machine | - | 1 |

| 4 | Automatic sealing machine | Set | 1 |

| 5 | Vacuum pump | - | 1 |

| 6 | Rewind bags, rectify, positioning conveyors | - | 1 of each |

| 7 | Palletizing conveyor | - | 1 |

| 8 | Gripper conveyor | - | 1 |

| 9 | Palletizing robot | - | 1 |

| 10 | Robot base | - | 1 |

| 11 | Robot gripper | Set | 1 |

| 12 | Automatic pallet storehouse | Set | 1 |

| 13 | Automatic wrapping machine | Set | 1 |

| 14 | Air Compressor | - | 1 |

| 15 | Install and debugging fees | Set | 1 |

| 16 | Taxes | Set | 1 |

| 17 | Freight | Set | 1 |