Study on Biomass Torrefaction Process

Torrefaction is a mild roasting process in an inert atmosphere, and temperatures are typically ranging between 200 and 300 °C. The treatment results in de-volatilization, de-polymerization and carbonization of the biomass. The products are a uniform solid mass of dark colour (torrefied biomass), and torrefaction gas. Typically about 70% of the mass is retained as a solid product. The solid fraction retains 90% of the initial energy content. This is the reason why the heating value of torrefied biomass is about 15-20% higher compared to untreated biomass.

Torrefied biomass has “coal like” properties and makes it therefore particularly suitable for firing in existing coal based CHP plants, and for industrial applications such as steel and cement production.

Wood is by far the most used biomass feedstock for torrefaction applications.Torrefaction technology can broaden the feedstock base for bioenergy utilization beyond wood resources, especially when combined existing with pelletization technologies. Combined torrefaction and pelletization can increase the energy density of biomass by about five times. It can also produce a biomass feedstock better suited for blending with coal, offering improved milling and handling characteristics and allowing the two to be blended prior to coal milling, which can potentially increase cofiring ratios.

It’s important to study the torrefaction properties of oil palm waste. The palm oil industry is a multimillion dollar business and results in huge amounts of waste products such as empty fruit bunches (EFB), mesocarp fiber and kernel shell. There is limited use for those kind of residues at the present time but they are very important feedstock for torrefaction processes.

The heating of biomass during torrefaction results in the release of gaseous products from biomass.The amount of combustible gases increases with temperature and reaction time. The calorific value of torrefaction gas has been determined to be in the range of about 5.3 to 16.2 MJ/Nm3.

Torrefaction gas is usually combusted on production site. SIMEC torrefaction processes use the heat obtained from its combustion in the process itself and also for biomass drying. It can also be used as inerting agent as per SIMEC process design.

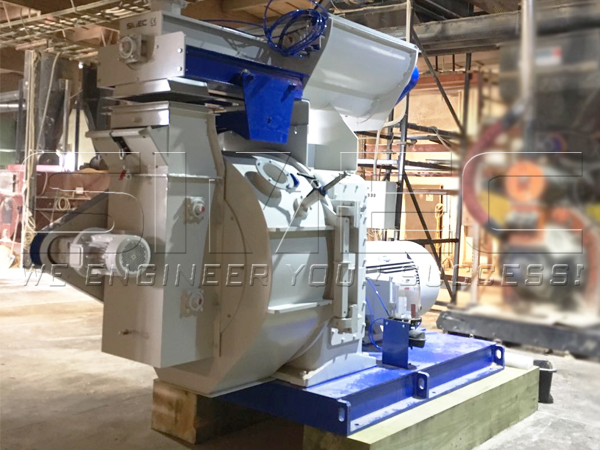

After initial start up, SIMEC torrefaction plant is set to run continuously without external heat source.Torrefaction gas will sustain the reaction. Equipped with full automation monitoring system, torrefaction grade can be regulated according to the setting of production data. The operation of torrefaction plant is fully automatic.

SIMEC torrefaction technology is developed to benefit industrial production of advanced solid biomass fuel. It provides a sustainable, green renewable energy source utilizing biomass and reducing carbon emissions.

© Copyright of articles and pictures on this site belongs to SIMEC. Any company, media, website or individual are not allowed to reprint, reproduce, repost, modify or use in other ways without permission. Otherwise SIMEC will have the right to pursue legal responsibilities.