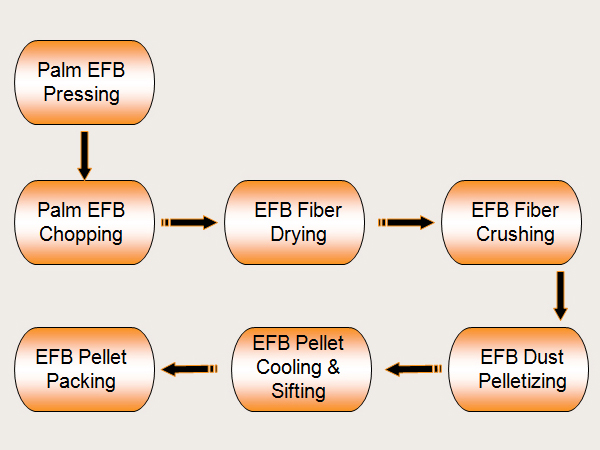

Steps to Process Palm EFB Pellet

I. What is Palm EFB?

The Empty Fruit Bunches (EFB) is one of the large amount residues from the palm oil factory, it contains neither chemical nor mineral additives. The moisture content of fresh EFB is around 67%, due to the high moisture and massive fibrous nature, it is difficult to transform the palm EFB into biomass energy. But there is a enormous potential of converting EFB into renewable energy demand for palm oil mills or other industries, that is to process the palm EFB into pellets.

The Empty Fruit Bunches (EFB) is one of the large amount residues from the palm oil factory, it contains neither chemical nor mineral additives. The moisture content of fresh EFB is around 67%, due to the high moisture and massive fibrous nature, it is difficult to transform the palm EFB into biomass energy. But there is a enormous potential of converting EFB into renewable energy demand for palm oil mills or other industries, that is to process the palm EFB into pellets.

Palm EFB

II. Why Palm EFB Pellet Plants are Increasing?

- EFB pellet with Low Moisture in Nature

- High Heating Energy and Efficiency

- EFB pellet Easy Handling and Storage

- Pellet Suitable for most of the boilers grating systems

- EFB pellet Generate Low to No smoke during the Combustion

- Easy Control and Broad application

III. How to Make Palm EFB Pellet?

1. Palm EFB Pressing

The moisture content of the Fresh EFB which comes directly from the Palm Oil Mill is reduced by the Press from approximately 70% m/c to 50% - 55% m/c, each EFB is usually torn into 3-4 discrete chunks.The juice which is squeezed out contains sludge oil from which 0.2% to 0.3% OER can be recovered by transferring the juice to the Palm Oil Mill's existing Oil Recovery System.

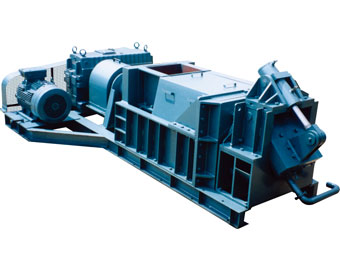

2. Palm EFB Chopping

Comparing with the traditional pretreatment to the EFB, SIMEC EFB drum crusher can directly shred and crush the fresh EFB with 70% moisture into 20-30mm length fiber without squeezing the liquid out firstly. The output fiber could be easily dried and fine crushed in the following EFB pellet processing, which guarantees the high quality of the final EFB pellets products.

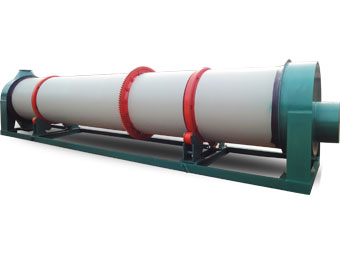

3. Palm EFB Fiber Drying

The single layer rotary dryer is exclusive for drying the chopped EFB fiber with high moisture. The anti blockage desgined shovels lift and shower the EFB fibers evenly through the hot air stream.

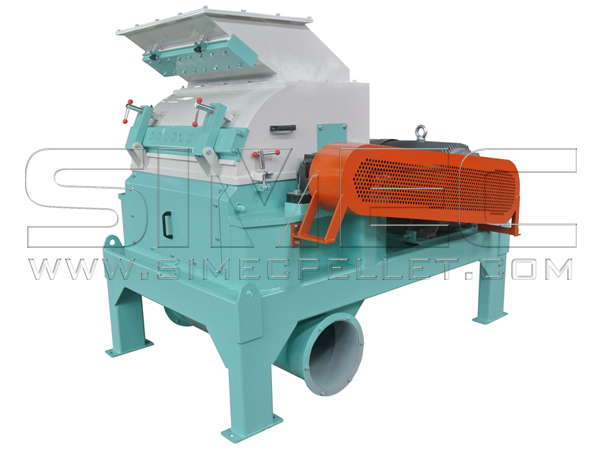

4. Palm EFB Fiber Crushing

It is professional pulverizer to process the EFB fiber into dust suitable for pelletizing. The pulverizing room is designed to be wide to crush the EFB fiber without blockage. Well balanced rotor makes the running very stable.

5. Palm EFB Pelletizing

SIMEC EFB dust pellet mills are improved from the SPM series hardwood pellet mill. We grasp the best ring die compression ratio for pressing out good quality EFB pellets. We now have five different models of pellet mills to choose from. The high precision driving system improves the pellet mill operation stability and power output efficiency.

6. Palm EFB Pellet Cooling

Cooling of pellets is an indispensable process of pelletizing section. Temperature of granules from pellet mill can be reduced from 70℃~90℃ to 3℃~5℃ higher than the room temperature by using the reverse-flow cooler, and to the required moisture(≤10%) for the convenience of pellet transport and preservation.

7. Palm EFB Pellet Packaging

LB350 fully automatic bag given packaging machine is the latest model of our company, it can achieve the steps of feeding bags, opening bags, clamping bags, filling the bags, output transport and fully automatic sealing, the whole process is unmanned operation. The machine unit is more ergonomic, easier to operate, convenient to switch the bag specifications and maintain the machine, the PLC controller parts adopt the international brands, the performance is reliable, the running of machine is stable and safe.

Please download the instruction of SIMEC Palm EFB Pellet Plant to know more detail information.

Please download the instruction of SIMEC Palm EFB Pellet Plant to know more detail information.