Rice Husk Pelleting Test by SPM350 Pellet Mill

In addition to producing wood pellets, SIMEC series pellet mills are able to process most kinds of the biomass raw material, such as rice husk, corn straw, wheat stalk, peanut shell, empty fruit bunch (EFB), palm kernel meal (PKM), king grass, etc.

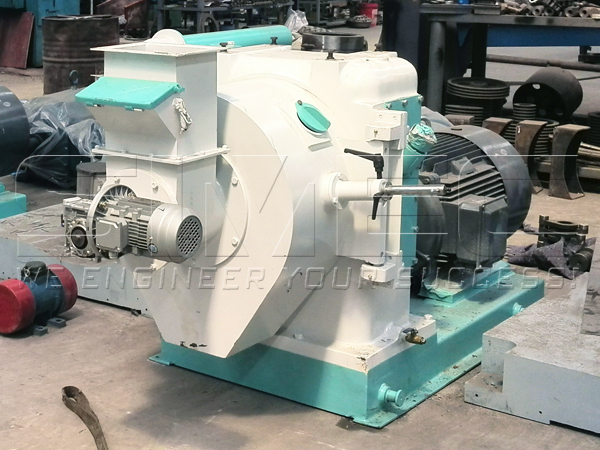

SPM350 Rice Husk Pellet Machie

One of our Indian customers would like to produce wood sawdust pellets and rice husk pellets for his pilot pellet project. The requested capacity is 400-500 kg/hr. The moisture of the rice husk and sawdust is 13%-15%, drying system is not needed. Both of the raw materials don’t need to be crushed.

Rice Husk Pellet Mill

SPM350 Pellet Machine

We recommend the SPM350 pellet mill to process his sawdust and rice husk. We test the rice husk pelletizing with the SPM350 pellet mill and take the testing video in our workshop, according to our customer’s requirement. No binder was mixed with the rice husk. The output capacity of 6mm rice husk pellets was stable, pellets were smooth and hard.

SPM350 pellet mill is suitable for the small scale wood pellet manufacturer, or the first pilot project. It has the below features.

- The driving gear adopts the high precision gear transmission structure. The ring die adopts the hoop fastening method;

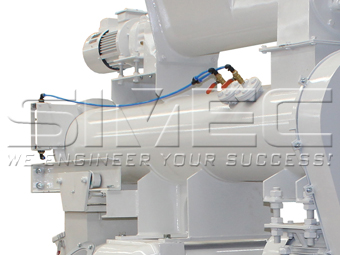

- The moisture adjusting system furnished on the pellet mill can adjust the moisture content, when the rice husk is too dry.

- The bio-pellet mill is equipped with auto lubrication system;

- To reducing the abrasion of wearing parts, improving the efficiency of working, reducing the damage and avoiding efficacy losing of machine parts caused by less lubrication, SIMEC adopts automatic lubrication system in order to extend the maximum life span of the pellet mills. The main shaft bearings and double roller bearings will be lubricated by the system;

- Our ring die is made of 4Cr13 alloyed stainless steel. Our carburizing treatment makes the depth of hard layer to be 2mm. Anti-abrasion ability of ring dies and rollers is improved more than 10 times, comparing with ordinary technology.

Moisture Adjusting System

Automatic Lubrication System

Rollers

Ring Die