Pyrolysis Upgrades the Value of Coffee Grounds

According to the International Coffee Organization (ICO), 650 kg of Coffee grounds are produced per ton of Coffee beans, and 2 kg of wet Coffee grounds are produced per 1 kg of instant Coffee. And regarding to the authority figures, on average, 400 billion cups of coffee are consumed worldwide each year.

That’s a huge consumption number. And in turn, it brings a large number of Coffee grounds which causes a waste of resources with more waste than edible part. So, how to reuse the Coffee grounds becomes a global research topic.

Actually, great commercial value can be created through coffee grounds pyrolysis.

A recent research by SIMEC shows that to pyrolyze coffee grounds can produce an abundance of combustible gas and high quality solid biochar.

Coffee Grounds

Coffee Grounds Pyrolysis

Without any size reduction treatment, the original size of coffee grounds is relatively suitable for pyrolysis laboratory apparatus. Raw material has about 23% moisture content. The input feeding process is very smooth and the pyrolysis reaction is faster than other material, such as rice husk, paddy straw, etc.

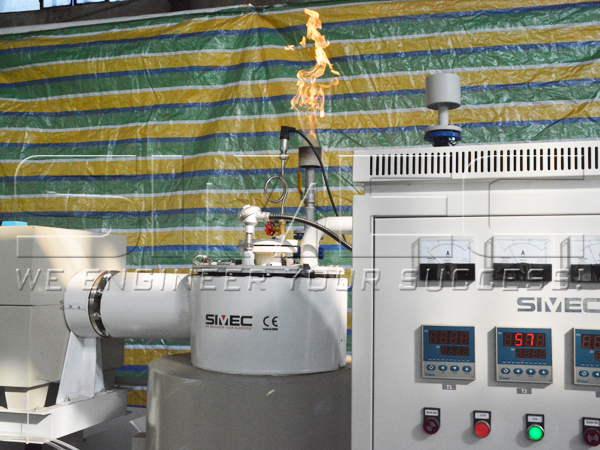

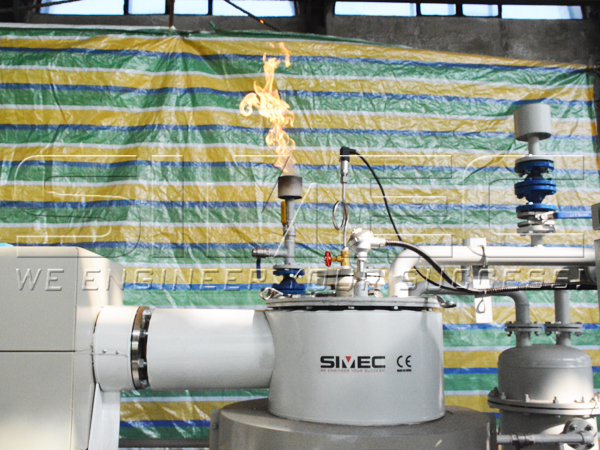

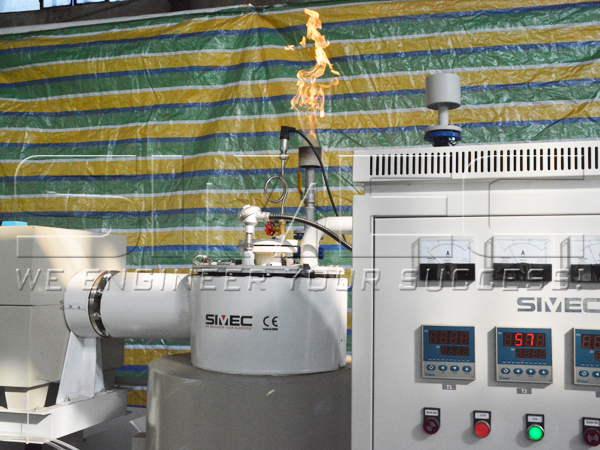

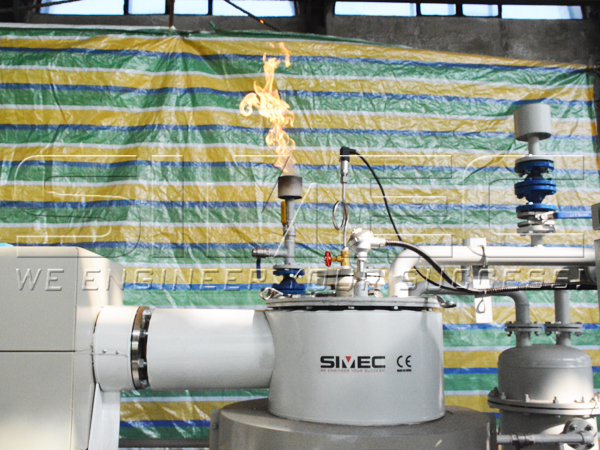

With 600 ℃reaction temperature and 25 minutes residence time, coffee grounds pyrolysis generates sufficient combustible synthesis gas. The flame produced by burning gas is strong and beautiful. Beside being used to sustain pyrolysis reaction, there’s still a mass of surplus synthesis gas which can be utilized for industrial heating or power generation.

According to SIMEC R&D test, 0.7 Kg of solid char was produced from 2.25 Kg of coffee grounds. Char production yield ratio is about 31%.

Coffee Grounds Moisture

Coffee Grounds Pyrolysis Syngas

Pyrolyzed Coffee Grounds

For coffee processing industries, coffee grounds is indeed valuable byproduct. It’s totally not waste material. With state of the art technology, coffee grounds can contribute commercial value in multiple ways.

Setting up a coffee grounds pyrolysis plant, the material can be pyrolyzed onsite without any additional transportation cost. The surplus synthesis gas can burn to provide heat for coffee processing factory. The excess heat of pyrolysis plant can also be recovered. So the fuel cost and heating cost can be reduced very much.

After pyrolysis, the coffee grounds based biomass char can be sold to organic fertilizer producers and activated carbon producers. Or be burnt as solid fuel onsite to reduce heating cost further.

With advanced pyrolysis technology, SIMEC has helped a number of coffee processing factories to upgrade the value of coffee grounds. We believe more clients will be benefited by SIMEC pyrolysis equipment.

That’s a huge consumption number. And in turn, it brings a large number of Coffee grounds which causes a waste of resources with more waste than edible part. So, how to reuse the Coffee grounds becomes a global research topic.

Actually, great commercial value can be created through coffee grounds pyrolysis.

A recent research by SIMEC shows that to pyrolyze coffee grounds can produce an abundance of combustible gas and high quality solid biochar.

Coffee Grounds

Coffee Grounds Pyrolysis

Without any size reduction treatment, the original size of coffee grounds is relatively suitable for pyrolysis laboratory apparatus. Raw material has about 23% moisture content. The input feeding process is very smooth and the pyrolysis reaction is faster than other material, such as rice husk, paddy straw, etc.

With 600 ℃reaction temperature and 25 minutes residence time, coffee grounds pyrolysis generates sufficient combustible synthesis gas. The flame produced by burning gas is strong and beautiful. Beside being used to sustain pyrolysis reaction, there’s still a mass of surplus synthesis gas which can be utilized for industrial heating or power generation.

According to SIMEC R&D test, 0.7 Kg of solid char was produced from 2.25 Kg of coffee grounds. Char production yield ratio is about 31%.

Coffee Grounds Moisture

Coffee Grounds Pyrolysis Syngas

Pyrolyzed Coffee Grounds

For coffee processing industries, coffee grounds is indeed valuable byproduct. It’s totally not waste material. With state of the art technology, coffee grounds can contribute commercial value in multiple ways.

Setting up a coffee grounds pyrolysis plant, the material can be pyrolyzed onsite without any additional transportation cost. The surplus synthesis gas can burn to provide heat for coffee processing factory. The excess heat of pyrolysis plant can also be recovered. So the fuel cost and heating cost can be reduced very much.

After pyrolysis, the coffee grounds based biomass char can be sold to organic fertilizer producers and activated carbon producers. Or be burnt as solid fuel onsite to reduce heating cost further.

With advanced pyrolysis technology, SIMEC has helped a number of coffee processing factories to upgrade the value of coffee grounds. We believe more clients will be benefited by SIMEC pyrolysis equipment.

© Copyright of articles and pictures on this site belongs to SIMEC. Any company, media, website or individual are not allowed to reprint, reproduce, repost, modify or use in other ways without permission. Otherwise SIMEC will have the right to pursue legal responsibilities.