How to Convert Oil Palm Trunk into Pellets

How to Convert Oil Palm Trunk into Pellets

——A Simple Mass Balance Calculation of Oil Palm Trunk Fibre Pelletizing Technology

——A Simple Mass Balance Calculation of Oil Palm Trunk Fibre Pelletizing Technology

As a common plant in tropics, Oil Palm Trees plays an important role at local economic. Worldwide 42 countries cultivate oil palm tree on about 27 million acres. Oil palm tree generally has an economic life span of about 25 years, and it brings a high amount of OPB waste, especially oil palm frond (OPF) and oil palm Trunk (OPT). For example, Malaysia is the world's largest producer and exporter of the oil palm. An estimation based on a planted area of 4.69 million ha and a production rate of dry oil palm biomass of 20.34 tonnes per ha per year show that the Malaysian palm oil industry produced approximately 95.3 million tonnes of dry OPB in 2009. This figure expected to increase substantially when the total planted hectarage of oil palm in Malaysia could reach 4.74 million ha in 2015, while the projected hectarage in Indonesia is 4.5 million ha. Oil palm industries generate abundant amount of OPB says in million of tons per year which when properly used for pelletizing as biofuels, it will bring great benefits to the investors for decades.

The biofuel pellets are popular in biomass power stations and will play an important role in power generation industry with ECO-friendly policies issued in most countries. After proper processing, its heat valve reaches 4,200~4,500 kcal/kg but has lower effluent to the environment, about 2.2% ash content.

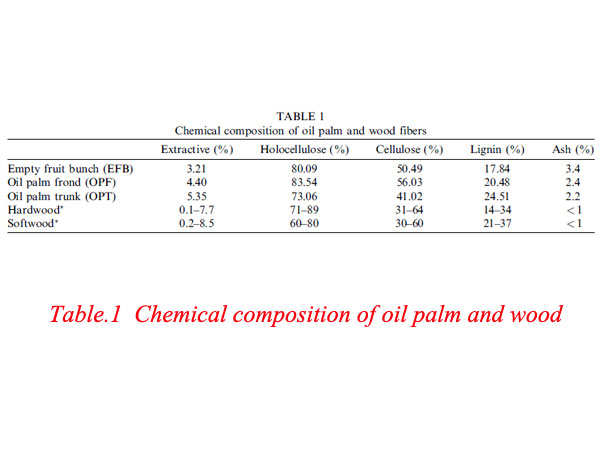

As per a recently research, the Table 1 shows the basic chemical composition of oil palm biomass.

Generally, OPT fibre (OPTF) showed the highest percentage of lignin (24.51%), followed by OPF (20.48%) and EFB (Empty Fruit Bunch) (17.84%). Its lignin ratio of OPTF lays in a medium level as Hardwood. Lignin is a desirable binder in pelletizing process. Its content decides the compression performance and compact condition of pellets. SIMEC is the forerunner who devotes to the technology of pelletizing for OPTF and our equipment and technique is developed for OPTF after years of R&D and practice in Malaysia and Indonesia.

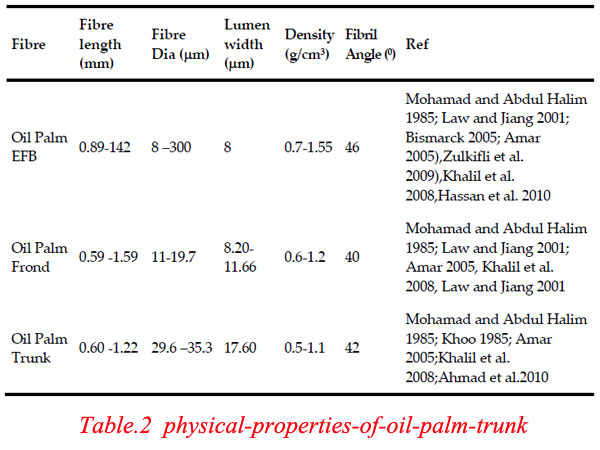

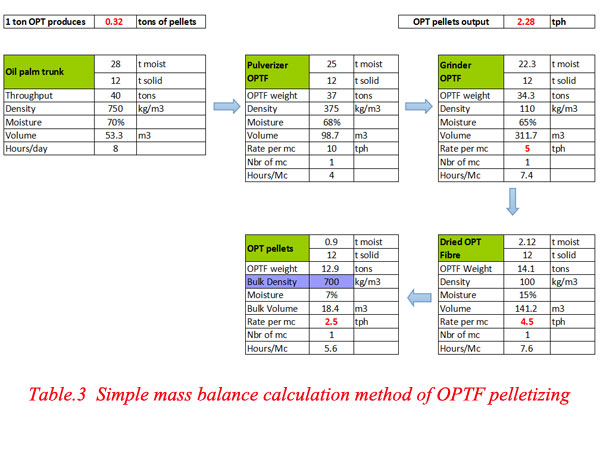

Let’s share a simple mass balance calculation method of OPTF pelletizing for investors. Please refer to Table 2 and Table 3.

Let’s share a simple mass balance calculation method of OPTF pelletizing for investors. Please refer to Table 2 and Table 3.

Table 2 shows us a reference density of OPT. Combined with our experience, we take an average value as 750kg/m3 for the calculation.

From Table 3, you can find and calculate the economy of 1ton OPT converted to pellets and have a general idea about the capacity of a OPT pellet plant which you should invest in.The quantities of process shows clearly,too.Please note that the key values based on our tests and practices.

If you met difficulties in OPT pelletizing investments or have plenty of questions about its pelletizing technologies, please feel free to contact us.We’ll suggest and offer complete solutions according to your requirements and conditions of materials.

From Table 3, you can find and calculate the economy of 1ton OPT converted to pellets and have a general idea about the capacity of a OPT pellet plant which you should invest in.The quantities of process shows clearly,too.Please note that the key values based on our tests and practices.

If you met difficulties in OPT pelletizing investments or have plenty of questions about its pelletizing technologies, please feel free to contact us.We’ll suggest and offer complete solutions according to your requirements and conditions of materials.