Cold Briquetting of Rice Husk Charcoal

Rice husk

Rice Husk Char

Record of Cold Briquetting Test:

Date: Nov 01, 2020

Feedstock: Rice husk charcoal

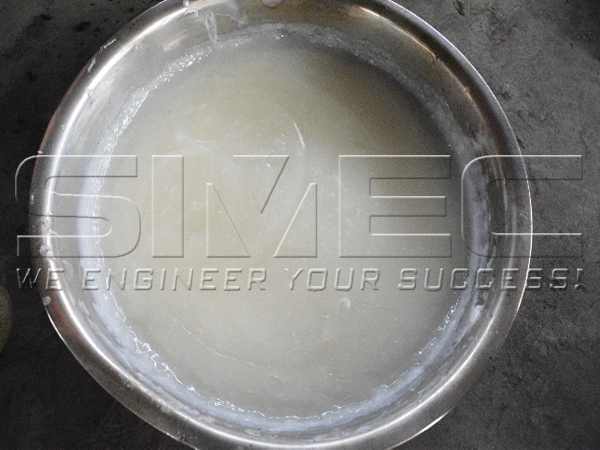

Organic Additive: Cassava starch paste

Pretreatment: Additive blended

Additive Percentage: 5%

Blending Equipment: Laboratory wheel mixer

Briquetting Equipment: SYY-1000 briquetting machine

Feedstock Weight: 1.43 kg

Before briquetting, the rice husk charcoal was blended with 5% cassava starch paste by a SIMEC edge runner mill for 10 minutes. As a result, the charcoal was milled and thoroughly blended with the organic additive.

Cassava Starch Paste

Edge Runner Mill

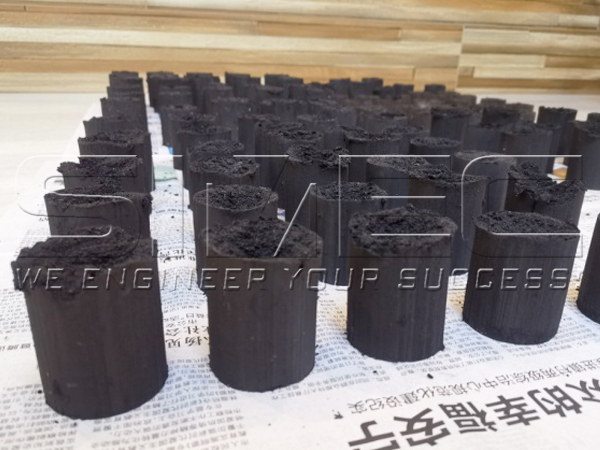

Then the blended feedstock was pressed into hollow cylinder charcoal briquettes by SIMEC SYY-1000 cold briquetting machine. The models for producing various shapes of briquettes can be customized. Briquette length adjustment can be achieved due to the pressure monitoring and regulating system.

The briquettes were dried by an exclusive dryer at 40℃ for 10 hours.

The dried briquettes are compacted and hard with high quality.

Cold Briquetting

Charcoal Briquettes

© Copyright of articles and pictures on this site belongs to SIMEC. Any company, media, website or individual are not allowed to reprint, reproduce, repost, modify or use in other ways without permission. Otherwise SIMEC will have the right to pursue legal responsibilities.