Cane Bagasse Utilization in Indonesia

Sugar Cane

While in Indonesia the residue-bagasse is usually thrown into the sugar factories’ boilers. While some problems can not be ignored caused by the wet bulk bagasse fuel (moisture content: 45%-50%). First of all, the low caloric value would reduce the efficiency of the boilers; secondly, large amount flue gas will exacerbate air pollution; And the bulk bagasse would generate a great deal of dust. In Indonesia, the bagasse is also used as the additional raw material of the edible fungus culture medium.

Sugar Facory

Sugar Cane Bagasse

But the above mentioned two kinds of utilization are primary and low-value-added. Due to the sufficient wood raw material resources, the bagasse has never been and would not be considered as the raw material in the pulping industry in Indonesia. For other uses, it would need advanced technology and huge investment. The best way to process the bagasse intensively is to convert it into bagasse pellets. The final pellets can be sold as high value cattle feed or solid biomass fuel.

Bagasse Feed Pellets

Bagasse Feed Pellets

The sugar cane bagasse contains many essential nutrition for the cattle, 44%-16% coarse fiber, 0.7% coarse fat, 1.5% crude protein, etc. The bagasse is a very good raw material of the feed for the ruminant animals, such as cattle, caw, sheep, goat, camel etc. Comparing with the bulk bagasse, the bagasse pellets has the two main advantages:

1. Through the pre-treatment process, such as size reduction, drying and pelletizing, the final pellets are very dry (moisture content <10%) and with high specific gravity, which are easy to be stored and transported. That greatly reduce the cost of storage and transportation;

2. During the pelletizing, the high temperature in the pelleting chamber can kill most of the bad bacteria, which makes the feed safer;

Bagasse Fuel Pellets

Bagasse Fuel Pellets

Bagasse pellets are also treated as a biomass energy in the biomass pellets market. Comparing with other biomass raw materials, the bagasse contains more around 20% lignin, which is much more than other biomass raw materials, such as straws, grasses, husks etc. The lignin would melt and functions as the adhesive during the pelletizing, which makes the bagasse easier to be formed into pellets than other biomass raw material. The pellet has a calorific value at 4.0 kilocalories per kilogram (kcal/kg) (or 4.5 kilowatt hours per kg). The bagasse pellets can be used as the fuel for industrial heating purpose.

Sugar Cane Bagasse Pellets

How We Make Bagasse Pellets

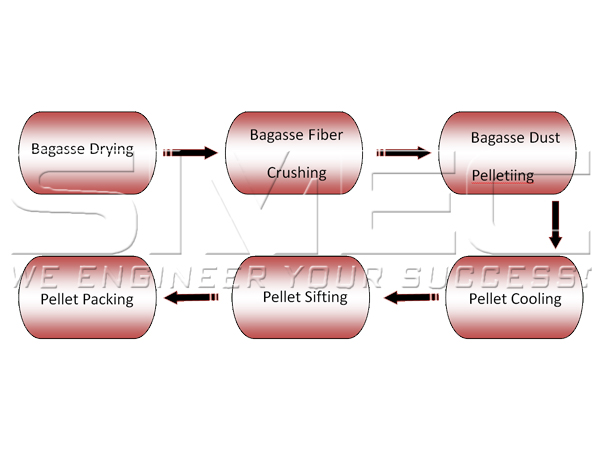

SIMEC, a professional manufacturer of biomass pellet production equipment, can provide the complete sugar cane bagasse pellet projects. Before pelletizing, the bagasse need to be pre-processed, such as size reduction, moisture reduction etc. Our detailed process technology is as follows:

Sugar Cane Bagasse Pellets Prducing Process

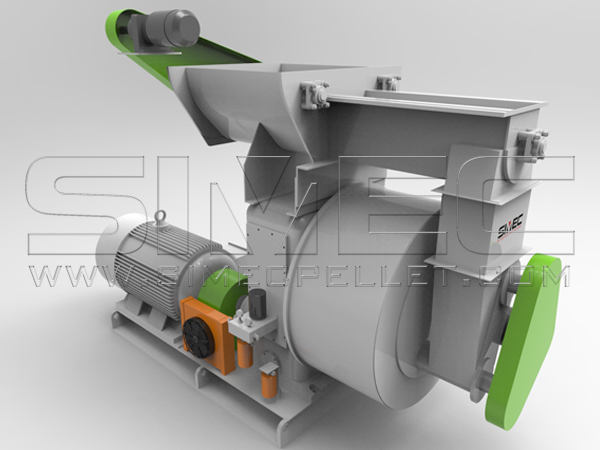

The exclusive bagasse single layer rotary dryer is able to reduce the moisture content from 40%-45% to 15%-18%. The dried bagasse fiber is crushed by the MFSP hammer mill. The bagasse dust output from the hammer mill is pressed into bagasse pellets in the SPM pellet mill. Based on the customer’s requirements and the acceptable standards, the pellet cooler and sifter would be needed, which can promote the quality of the bagasse pellet. The final pellets can be packed in jumbo bags or 15-50 kg small bags.

SPM780 Pellet Mill in Sugar Factory

Bagasse Pellets

SIMEC is always committed to provide you with the most suitable biomass pellet making proposal. We engineer your success!