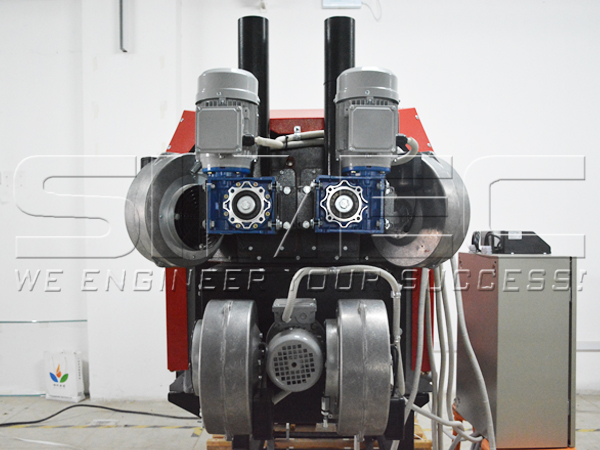

Automatic Pellet Burner SAPB1500

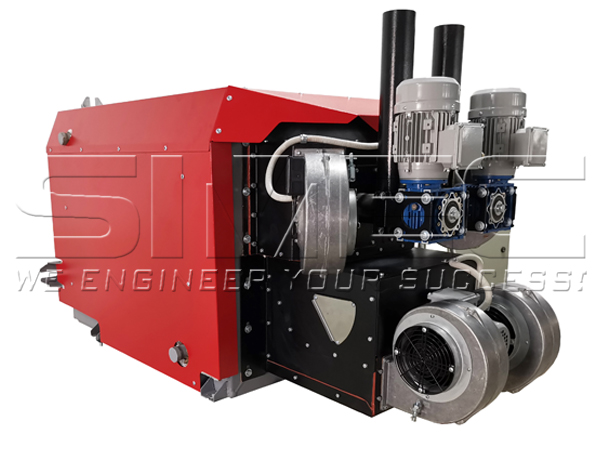

SAPB1500 Pellet Buner

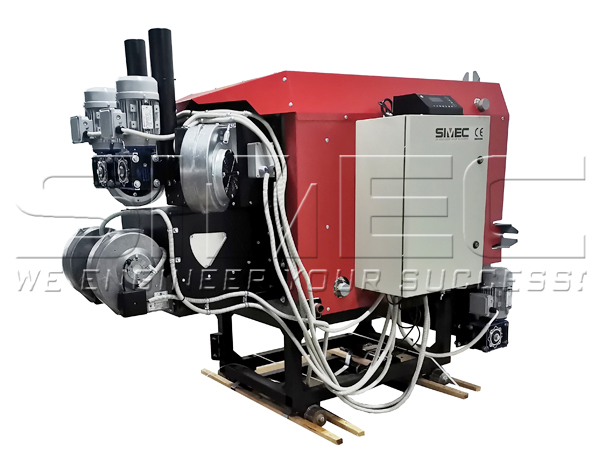

SAPB1500 Air Pellet Buner

Compared with the conventional pellet burner, the SAPB series pellet burner is distinguished by higher combustion efficiency up to 95%, lower pellet fuel consumption, fully automatic operation, available for remote monitoring, automatic cleaning, and easy maintenance.

It can serve as the initiative heat supplier or replace the existing fossil burners. The pellet consumption to reach the maximum capacity is only 300~350 kg/hour based on burning various kinds of pellets. As a result, the fuel cost can be reduced by maximum 30% compared with the fossil burners. Therefore, high combustion efficiency and low fuel consumption can both boost users’ profits.

Most important of all, the utilization of pellet burner greatly contributes to reducing carbon footprint.

Parameters:

| Heat Power (adjustable) | 300~1500 kW/hour |

| Power Voltage, V | 3 Phase, 380V, 50Hz or Single phase, 220, 50Hz |

| Fuel Consumption | 300~350 kg/hour |

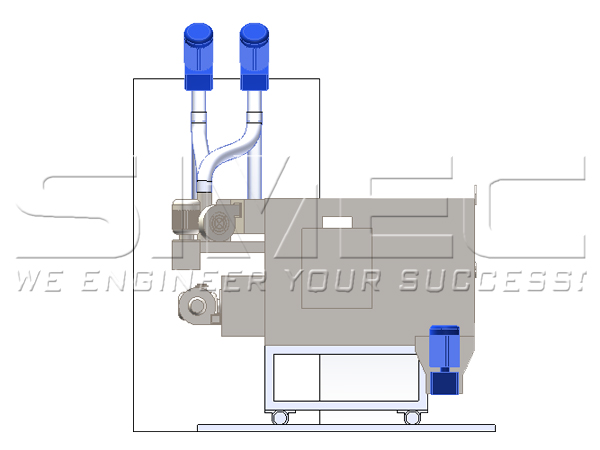

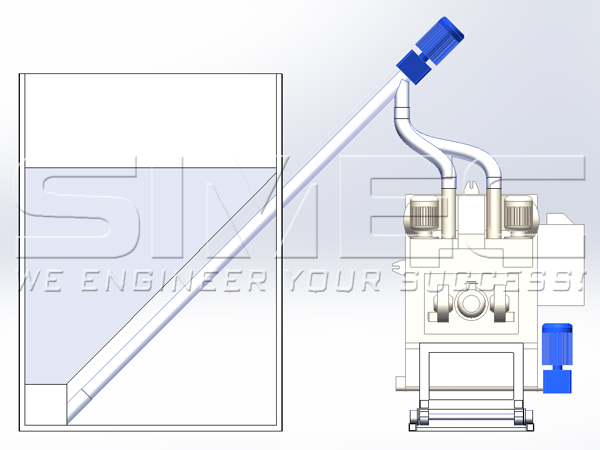

| External Pellet Feeder | 2 x 250 watts |

| Internal Pellet Feeder | 2 x 250 watts |

| FD Fans | 4 x 400 watts |

| Trailing Grate System | 250 watts |

| Automatic Cleaning System | 250 watts |

| Overall Size | 1768 х 992 х 1500 mm |

| Burner Weight, kg | 1066 |

The burner and sliding rail mechanism were mounted in SIMEC workshop. The user needs to simply assemble the pellet silo, external feed feeding system and ash box on site.

The full-fledged pellet burner can deliver optimum performance in light of the following advantages:

Simple & Smart Operation

All functional units of the entire pellet burner system are monitored by an intelligent controller. Therefore, fully automatic operation through a one-button startup can be achieved. The hot water temperature or the hot gas (used for drying system) temperature can be dynamically regulated. The controller makes the operation secure and manageable.

Fast Ignition & Stable Flame Performance

Traditional pellet burner system features high preheating periods. It always takes a long time to ignite and reach the desired temperature. The ignition system is fast responsive and can quickly achieve full power offering with a stable and performing flame. The high-quality flame can be observed in regular shape and strong radiance, it is the result of constant and intense study on the combustion dynamics.

High Combustion Efficiency

As a result of continuous R&D and optimization to the entire combustion process, the combustion efficiency can achieve up to 95%, when the burner serves different purposes of heat supplying. This turns out to be no tar deposits on the walls.

Automatic Ash Cleaning System for Low Emission

The automatic ash cleaning system is mounted at the bottom of the flame outlet of the burner. It works synergistically with the combustion system, ensuring that most ash and sludge are cleaned up in time. As consequence, the emission is low enough to meet regulated standard.

Automatic Cleaning System

Industrial Pellet Burner

The combustion chamber is surrounded by newly developed refractories. The advanced heat-resistance material greatly protects the combustion chamber and reduces the spare parts consumption.

Water Cooling System Enhances Performance

The pellet burner is equipped with a water-cooling system for enhancing the performance during constant operation. This cooling system is monitored by the intelligent controller.

Resilient Replacement to Existing Burners

The pellet burner can replace all kinds of burners fueled by fossil energy like natural gas, diesel oil, and LPG as the equivalent capacity without renewing the boilers. Easy installation and small footprint.

Applicable to Low-Quality Pellet Fuel

Thanks to the unique design of the combustion chamber and correct distribution of the air flow inside the chamber, even the low-quality pellet fuel can be burnt efficiently. The distributed air volume inside the combustion chamber can be regulated automatically by the intelligent controller.

Durable and Reliable

The outstanding durability and reliability of the pellet burner rely on sustained R&D and stringent manufacturing procedures. The final product with a good appearance and compacted design is capable of serving for more than five years. Spare parts are scarcely needed.

SAPB1500 Pellet Buner Controller

Automatic Pellet Burner

For more information about the SAPB1500 pellet burner, please download the following document:

Operation Manual of SAPB1500 Pellet BurnerOpen password is available for SIMEC customers.

If you don't have the read permission, please contact info@simecpellet.com.

© Copyright of articles and pictures on this site belongs to SIMEC. Any company, media, website or individual are not allowed to reprint, reproduce, repost, modify or use in other ways without permission. Otherwise SIMEC will have the right to pursue legal responsibilities.