About Bana Grass Charcoal Briquette

Excessive emission of fossil CO2 is known to be a primary cause of global climate change. CO2 exhausted from the steel industries account for 5%~6% of global fossil CO2 emissions. Biocarbon could be used to replace the coal or coke employed to smelt iron ore and thereby reduce fossil CO2 emissions. Bana grass, a cultivar of elephant grass (Pennisetum purpureum, Schum.), which can produce amounts of biomass in a few months, is a promising biomass candidate for charcoal production.

Fossil CO2 Emission

Bana Grass Plantation

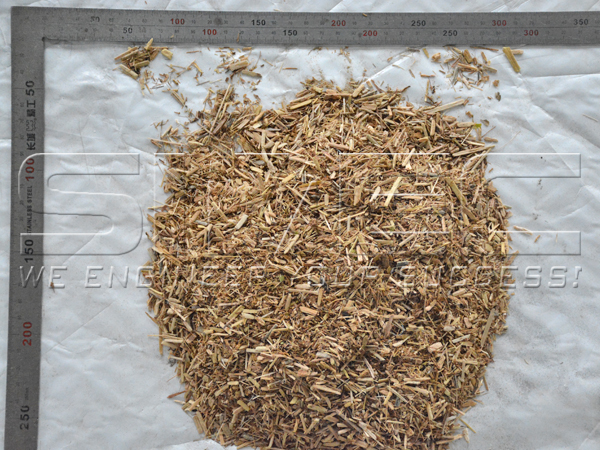

Dried Bana Grass

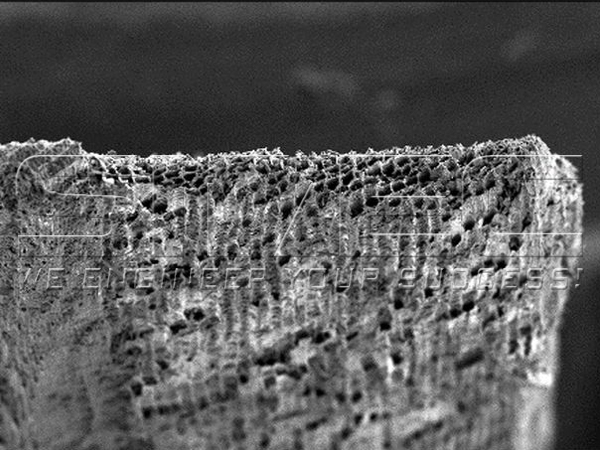

Besides, there is interest in the use of bana grass biochar as a soil amendment in agricultural soils due to its distinguishing characteristics of high carbon content, high pH, high stability, high porosity, and high surface area. The biochar greatly contributes to improving soil health and reducing the use of chemical fertilizers.

Bana Grass Charcoal Holes

Biochar Soil Amendment

It is proven that mature bana grass, after 4-6 months of growth, provides the highest yields of bio charcoal. SIMEC has a great amount of experience in converting the mature bana grass into valuable biomass charcoal.

Pulverized Bana Grass

Pyrolyzed Bana Grass

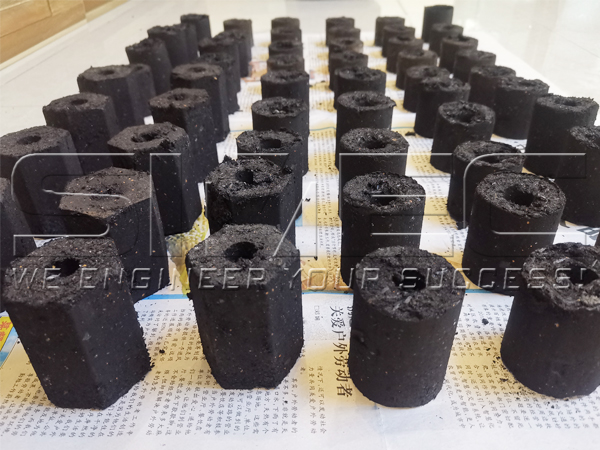

Bana Grass Charcoal Briquettes

Successful carbonization of bana grass was conducted on SIMEC Laboratory Pyrolysis Apparatus a fortnight ago. After being pyrolyzed, the charred bana grass was pressed into hollow cylinder briquettes.

Additive is indispensable to briquette production. Before briquetting, 5% performed cassava starch paste, employed as the organic binder, was blended with the bana grass charcoal evenly. The organic binder contributes to compacted and nontoxic charcoal briquettes.

Organic Additive

Blended Charcoal for Briquetting

Cold Briquetting Process

Bana grass charcoal was cold briquetted by a hydraulic briquetting machine which is designed to produce various shapes of briquettes. Its design capacity is 800~1000 KG/Hour charcoal briquettes.

It consists of buffer silo, hydraulic station, control system, and briquetting module. The intelligent control system makes the briquetting pressure adjustable. Therefore, different varieties of biomass charcoal feedstock can be briquetted at proper pressure.

The charcoal briquettes will be dried in a dedicated chamber dryer for 8 hours at 40℃ temperature. Then dried briquettes will be tested accordingly.

Bana Grass Briquettes

Bana Grass Charcoal Briquette

As prospectively promising biomass material, bana grass has been favored for producing biomass charcoal products thanks to its fast-growing feature and high yield of fixed carbon. Deep in biomass pyrolysis for a decade, SIMEC can furnish our clients with A to Z project solutions for the production of bana grass charcoal briquettes.

© Copyright of articles and pictures on this site belongs to SIMEC. Any company, media, website or individual are not allowed to reprint, reproduce, repost, modify or use in other ways without permission. Otherwise SIMEC will have the right to pursue legal responsibilities.